Custom-Fabricated Blower for Tek 2465

I've been quietly accumulating an assortment of of 75-80mm fans of various depths and types; going to do a "Hack 'em all, let God Sort 'em out" shootout.

Looking for ideas on some valid means of comparison-testing their effectiveness... haven't even arrived at a methodology yet. Maybe some kind of homebrew anemometer stuck to an airbox box around the U800 vent?

Doubtful any of them could pull more than a few mm H2O vacuum... even the OEM one, of which I have an excellent example in just-refurbished condition for baseline testing.

Please, let me know what y'all know of that I could might build as a test rig,

mnem

*cogitating-ily*

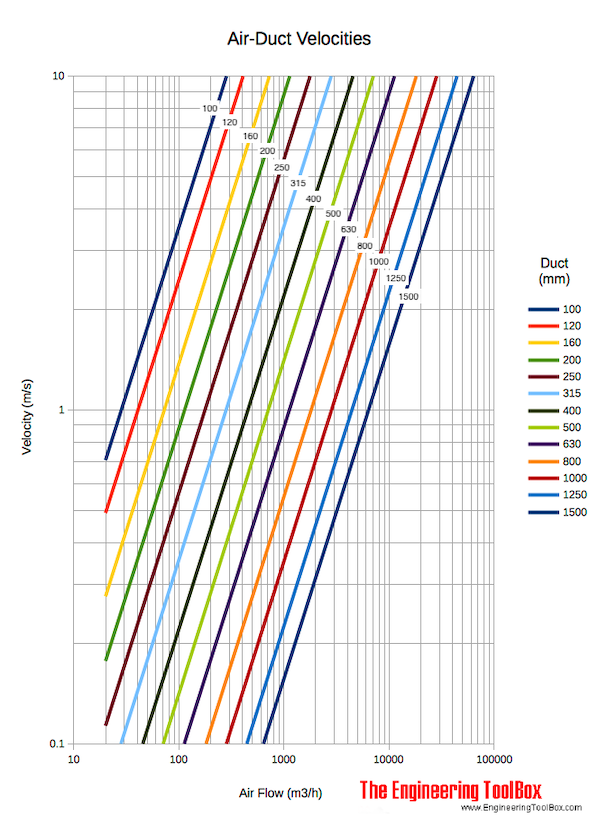

Only real Measure for these sort of fans is flow rate in a given duct area. Flow calculated from airspeed meter sitting in that duct either a heater or fan type. I have had a small handheld for years from my R/C glider flying and scoredstole this far more accurate industrial one for looking at Coffee Roaster airflow eBay auction: #303122786600

So you create this sort of thing

So you create this sort of thing

Even if your fan doesn't cover the entire duct can be mathematically fudged by looking at the likely airspeed distribution across the duct as the result of skin friction (second year Fluid Mechanics) but that is OTT. Might be some applicable reading here I just found https://www.cedengineering.com/userfiles/How%20to%20Size%20and%20Design%20Ducts.pdf

Yeah, I'm aware. I learned much of this in HVAC classes when I was a teenager, and again in Tech college for cooling solutions design. have one of the cheapie anemometers bought from Banggood years ago... from the vent at U800, it wouldn't even budge the vanes on my working 2465. Gonna need something a bit more sensitive; probably something not using a magnetic sensor.

The problem here is NOT measuring the fan... we already know what CFM the replacement fans in question are rated at. What we need is a measure of the flow

in situ. That's the only way we can make a meaningful comparison against the original fan, especially once I start hacking the fans to make them fit... or to compare something like the one I modded against the original.

Manual Here

Manual HereThis

Mastech MS6252A seems to be a quantum level better on all fronts than my little cheapie though; its impeller is easily twice the diameter, so the meager airflow from that vent may have enough leverage to actually move the thing.

It's rated down to FT/Sec ranges with 2 decimal points as well modes for for CFM. Mine has no volume scales and only goes down to M/sec with 1 decimal point; I remember being very disappointed in mine as it appeared to be more for sailing and surfing than HVAC, which was what I wanted it for. This MasTech appears to be intended for HVAC work... Hmmm...

Theoretically wouldn't the best measure of their effectiveness be how well they do their job? That meaning that temperature could show you directly how they stack up.

I don't know, maybe I'm missing something or maybe I'm an idiot. Yeah.. I'm probably an idiot.

Well, we have multiple things we're testing for here; with temperature-controlled variants vs non-temperature-controlled models in the mix, so just "temperature" is not necessarily a good yardstick. Where do you measure that temperature? What is a passing grade? For units that exceed the need, what other pros and cons matter?

For example, compare two identical blowers: One thermo-controlled and one running ballz to the wallz all the time; the latter will always run cooler. That doesn't mean it necessarily does a better job; it'll also be making the most possible noise all the time too, which is a consideration for SOME users.

Evidently noise was a consideration for the engineers at Tek; they designed the original blower with temp control. Or perhaps, their intent was to make the scope equalize temperature quickly so it could be "warmed up and stable" as soon as possible after power-up.What I'm trying to do is evaluate a number of commonly available fans of different type and features for a complicated rubrik that boils down to

BEST SUITABILITY AS A REPLACEMENT for the fan in the 2465. I'll be using the stock blower and my "severely modded server fan" blower as the yardstick; but maximum airflow in situ compared against a stock 2465 is only the most basic go/no-go minimum standard for suitability. Subjects that don't pass that grade will be dropped with extreme prejudice.

Other important metrics will be Cost, Easily Available, Effectiveness, Quiet vs Thermal Control, and especially Assache Factor in terms of how aggressively they'll need to be hacked in order to use them in the application; my modded server fan will probably be "worst case scenario" assache-wise since it essentially required my weird hand-fabbing skillset and freehand lathe work to make it happen.

Argue your limitations and they're yours.

Here's a starting point. With the old fan I did a temperature measurement on the back plate. Ambient temp was 74 F. I had the thermocouple in place for several hours and the temp never exceeded 97 F.

You mean the back aluminum plate of the chassis, where the fan, IEC socket, etc pass through?

*added to my test data*

mnem

*fighting a sudden surge of tool-dwagon acquisitiveness*