After leaving the unit on for about a week, it was clear that it was not meeting its stability spec and some repairs were needed.

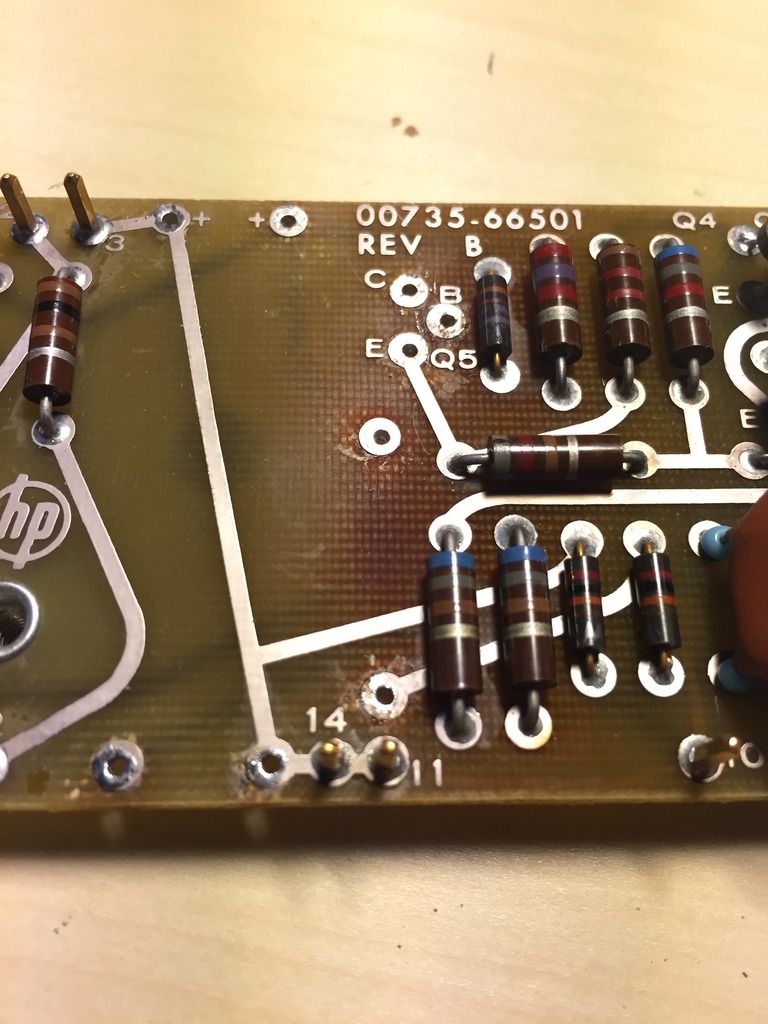

First order of business was to repair the A1 power supply and preregulator board. I had noticed a bit of browning on initial inspection. Once removed, it was clear that the board had been exposed to excessive heat for quite some time. The epicenter was under the resistor that feeds into the preregulator for the reference circuit. I replaced both capacitors, the resistor and transistor. The transistor had been replaced before and the work wasn't quite up to par.

Desoldering was a bit tricky. The board did not tolerate heat very well at all, even with the iron set at 500. One pad began to lift in the process, but I was able to remove the heat before it was lost.

And with the new parts, which cost around $20 given that they were hard to find:

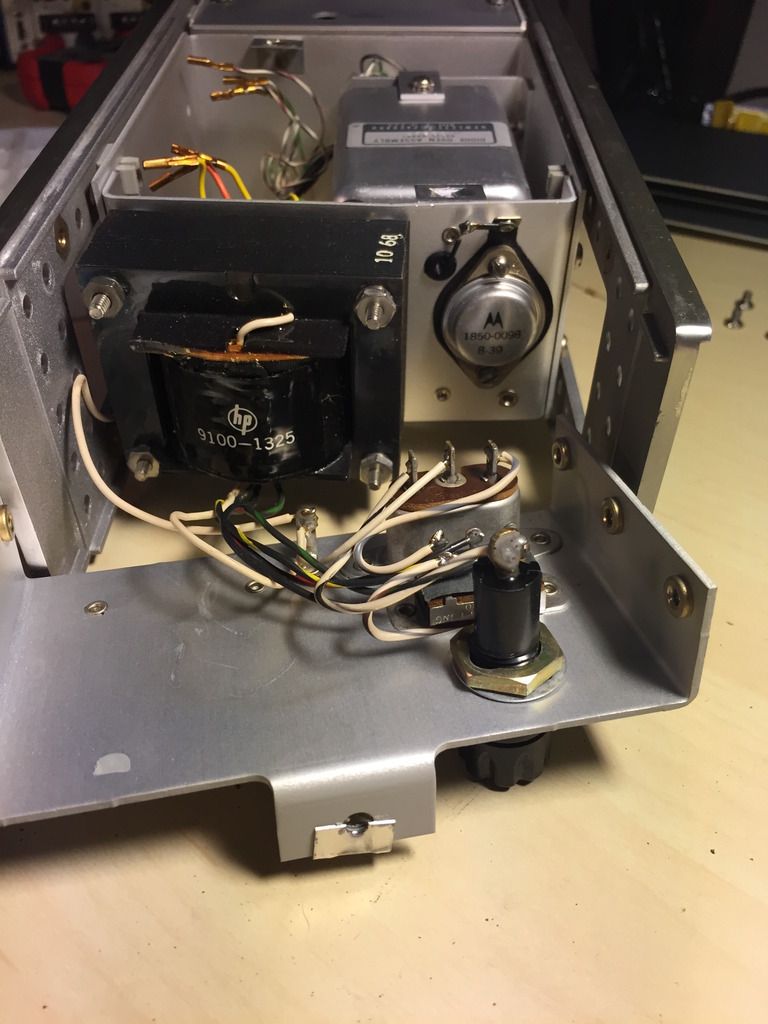

The next issue was that the unit had apparently been dropped at one point, causing the heavy transformer to deform the aluminum frame. As a result, the aluminum box had a gap that likely had an effect on temperature. This also caused the mains leads to be wedged between the transformer and outer case.

Despite the few dings and dents, I'm amazed at how new these parts looked. I have a few other HP devices from the late 60's and the transformers are all paper wrapped and come to me pretty rusty. This one looks brand new with no rust to be seen. Only sign of age is the "10 68" stamped on top. You can also see where some of the plastic had transferred from the mains wiring to the back case.

Very gently bent the case back into position without having to remove components. The unit was also humming rather loudly so I took the opportunity to crank down the transformer bolts with a ratchet. Silent ever since. I also removed Q1 to add some fresh thermal paste. Quite a hassle and probably wasn't necessary. Job done:

With the functional components repaired, I took a few minutes to give the exterior panels a facelift. Magic sponge+Goo Gone followed by IPA, then clean water and finally a light coat of McGuires Ultimate Black. The high gloss faded a bit after a few days and it looks pretty good, IMHO.

I've had it powered on for the last week or so and its remarkably stable. Maybe +/-3ppm noise. +/-1ppm transient drift as best as I can tell. My next project is to get my DMM's connected to a controller for data collection and will hopefully have some real numbers. Hope someone got some enjoyment out of this. I'd still like a couple more of these units!