There's been a couple of different threads about reflow ovens but mostly people asking if anyone owned one. Instead I'm writing this thread as a (long) summary of having recently purchased the T-937M. I'm still learning it and if there's anyone else with it that can offer up their experience that would be great.

The T-937M doesn't appear on their website, compared to the T-937 it has a bigger drawer 350x400mm with a usable area listed as 290x375 for lead free and 315x375 for regular solder. 3300 Watt heater.

I ordered it directly from them (via Dragon Group, the parent company). I had a couple of questions such as the information said 220V 50 Hz in one place and 50/60 Hz elsewhere. They got back to me within 24 hours on the requests. (60 Hz is fine)

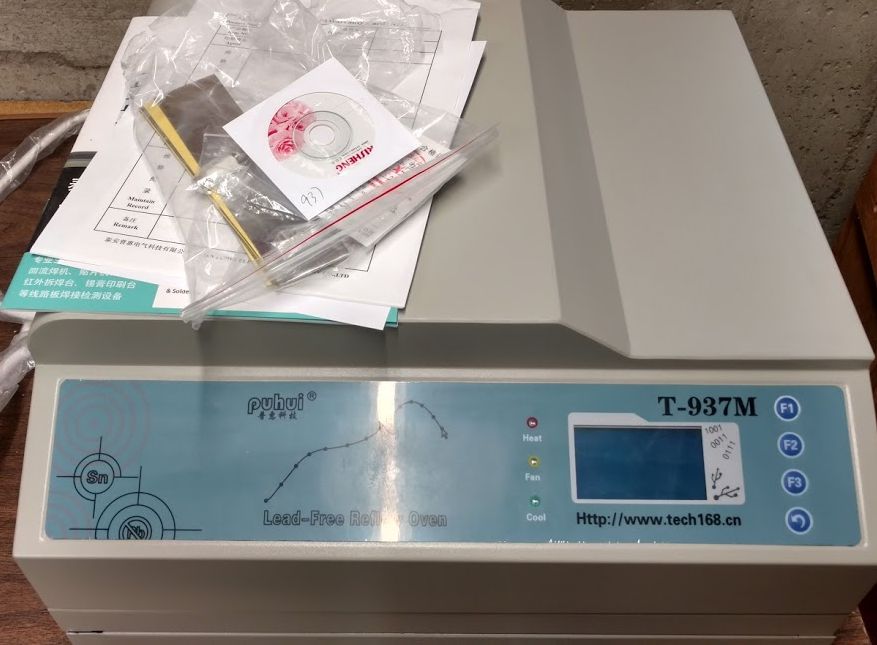

I ordered and they sent me a Paypal invoice (around US $720 total with shipping to me in the Boston area) and the package arrived about 8 days later. The box was a bit dinged up and some the styrofoam paking had cracked but there was no signs of damage. (for something of this weight (22 kg) probably a double box would hold up better)

(I cut the straps to remove the docs that came with it)

I changed the plug to match US 220V 20A outlet style (they double checked with me to make sure I understood it wasn't a 120V machine and I would have to change it, though oddly enough they included a US 120V 15A plug in the box). The yellow wire in the cord was the safety ground, here it's usually green.

They provided a metal exhaust hose, some foil tape (not sure exactly what for as the exhaust hose clamps on), a spare fuse, a serial to USB adapter, and a CD.

The CD wasn't readable and the files are not on their website, I emailed them and got an email back with the files the next day. The manual (in English) is provided as a pdf but it doesn't give a lot of information.

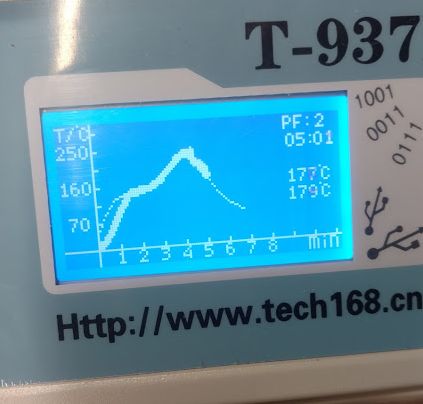

The unit can run without a computer so I tried the built in profiles first with it empty. The light line is the profile temp, the heavy line is what it measures (I'm guessing the sensor is on the top side of the chamber but I didn't look for it)

No odd smells even with the exhaust vent not actually routed outside. A slight "new paint" smell that faded. Only place that gets hot to touch is the drawer front, which isn't insulated. The small fan that runs all the time for the controller has a bit of a whine, but the machine overall isn't loud.

The USB driver Puhui supplied wouldn't install but it uses the CH340 and I grabbed a recent driver for that and it installed fine (Windows 7). The Puhui app installed OK though it seems like it needs to be run as administrator as otherwise it doesn't seem to save changes. I did not look to see where it's trying to keep files, etc.

I haven't total figured out the app, it has three databases it keeps for solder paste profiles (and comes with quite a lot, but I had to add my Chipquik paste), a recipe (which you create by drawing over the solder paste profile to adjust the time/temps to get the results on the board you want), and a manufacturing one which I haven't tried to figure out yet but seems like it lets you save away the setup and measured temps.

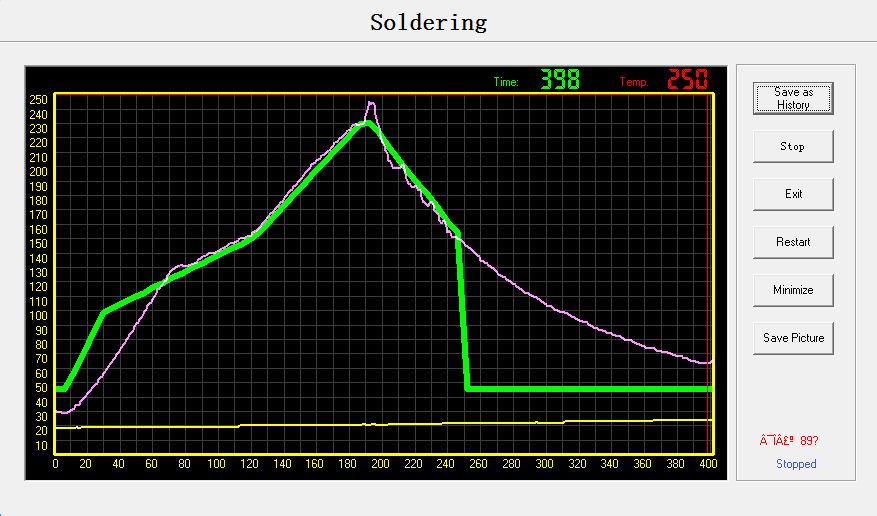

When it's running it replaces the setup screen with a run-time screen that shows what it's doing.

The green line is the target, the purple is what it measures. You can see that the initial ramp I put in is too fast and it doesn't catch up until the soak period. OTOH this was the first run so the unit was cold, it does a little better on later runs but I'll probably extend the initial warmup time. For cooldown it draws in room air and it can't really drop too quickly. Opening the drawer a little helps. If you terminate the run the exhaust (cooling) fan stops.

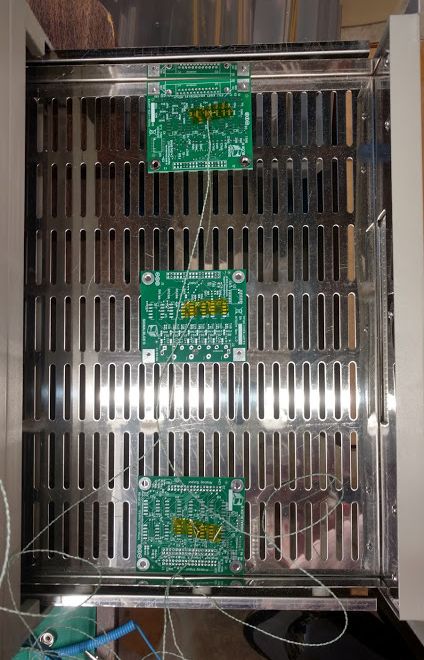

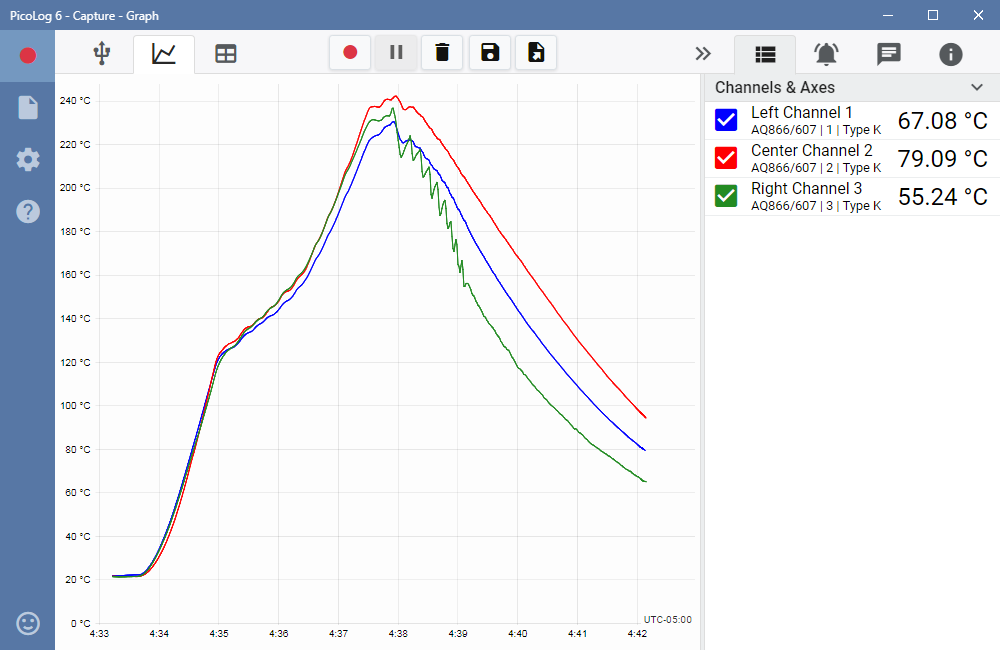

I have 3 thermocouples so I attached them to some small leftover PCB blanks and ran the oven with them arranged across the middle and then centered front to back. The outside sensors are somewhat over the edge of the area they define as usable and at some point I'll try one large board and measure across it.

(Left center right measurement locations)

Measured temps on PCB with peak setpoint of 235C.

The center measurement location typically shows it hits the desired temp, with the left and right about 10C less. The results seemed consistent but I didn't try and characterize beyond eyeballing the curves.

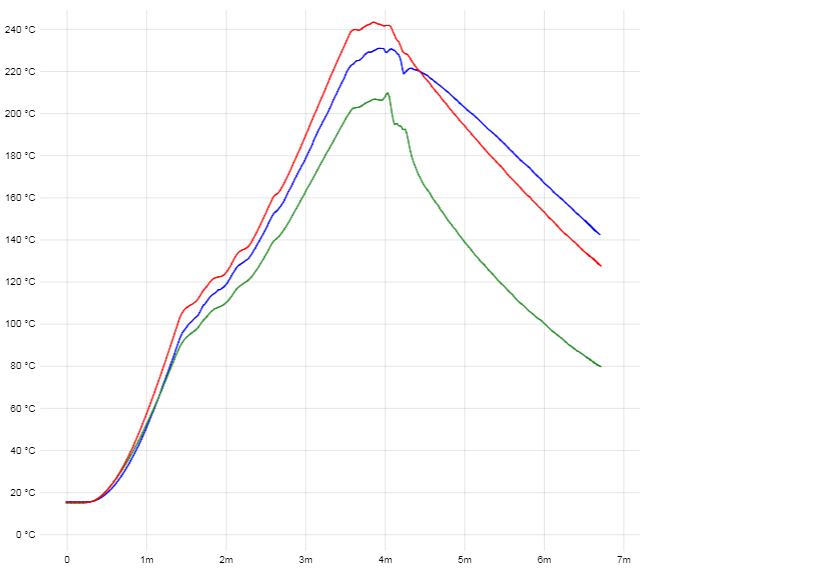

Front to back showed considerable variation.

(red middle, green front, blue back)

The front area stays around 25C cooler than the middle so I'm planning to not put anything in the front 1/4 until I figure out where the drop off is. Given the defined usable area in the datasheet I think this probably falls "in spec" but it would be nice if the manual gave some guidance as to *where* they think the usable area is.

I have a Sense power monitor and it shows 3600W used when the unit is running, but my "220" is actually 240 so that probably covers the higher than advertised number I measured.

I've run 3 different SMT board types through it (same sizes as used for the measurements) with regular solder and the results look really good compared to my previous IR hot plate/hot air method. I've got a lot more things to try but so far for what I wanted (easy to use, consistent results for small prototype batches) it seems pretty good, and the whole purchase process/experience dealing with Puhui/Dragon was positive.