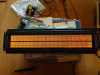

So well... It's *almost* alive!

I can see the sweep in the "dead" rows, so it's either something along the data bus being dead, or my test jig made out of two hex spinny things is not making good contact — the tube is most likely alive.

The panel plus it's boost converter eats a whoppin' 25W in this state — guess making a wall clock out of this is going to cost a pretty penny in electricity :/ Not to mention the flicker.

Also the logic alone still eats around 3W, which IMO is too much for what it is — I'll have to look more into what might be broken.

Otherwise replacing 4 of the 157 triggers and a 393 counter seemed to have mostly fixed it (and I'm not even sure about the counter, it just looked sus).

Along the way I've figured out the pinout of the data connector. Looking into the connector on the board, starting from the top right pin (where the white arrow is), counter-clockwise:

1 to 8. Bitmap data input

9.

(output)

10. ~CLK

11. ~RESET

12. ~RETZ

13. ~READY

14. BRIGHT

15. SHOW

16. Common

After powering on, wait until ~READY goes low.

To draw something on the display, you set the data pins to the top left 8 pixels and pulse ~CLK low. Then bottom left 8 pixels and pulse again. (or the opposite, depending on how you rotate the tube)

To hide whatever is shown on display, you pull SHOW low. That blanks the screen while letting you draw into the framebuffer. Also you can pull BRIGHT low to reduce brightness to about half of the normal level.

If you want to start drawing from scratch, pulse ~RETZ low. This resets the pointer to the active byte to 0 and you can draw from the top left again.

If all things went sideways, pulse ~RESET low and the board initializes itself, clearing the screen in the process. Of course then you have to wait until ~READY is low again before sending any data.

Now here's a question: while drawing this picture on the display the pixels in the middle struggled to light up until they went to around 2/3 through the screen. I keep the HV supply at 160V. Should I be increasing the HV, or is something in the drive circuitry still odd?

Upd: the dead row of pixels was just a wire falling off from my hex input test jig, reattaching that fixed it. I'll buy proper ribbon cable on my trip to Akihabara next week

Looks like it's all working now! Time to buy some shift registers and start coding, sawing, gluing and whatnot!

Thanks everyone for your help!!