Hello all. Good news!

It's been a few months since the last post on this passenger seat occupancy sensor. There's been times I've thought the 'Last Post' would be quite appropriate.

However, once back from a trip (go on, ask where

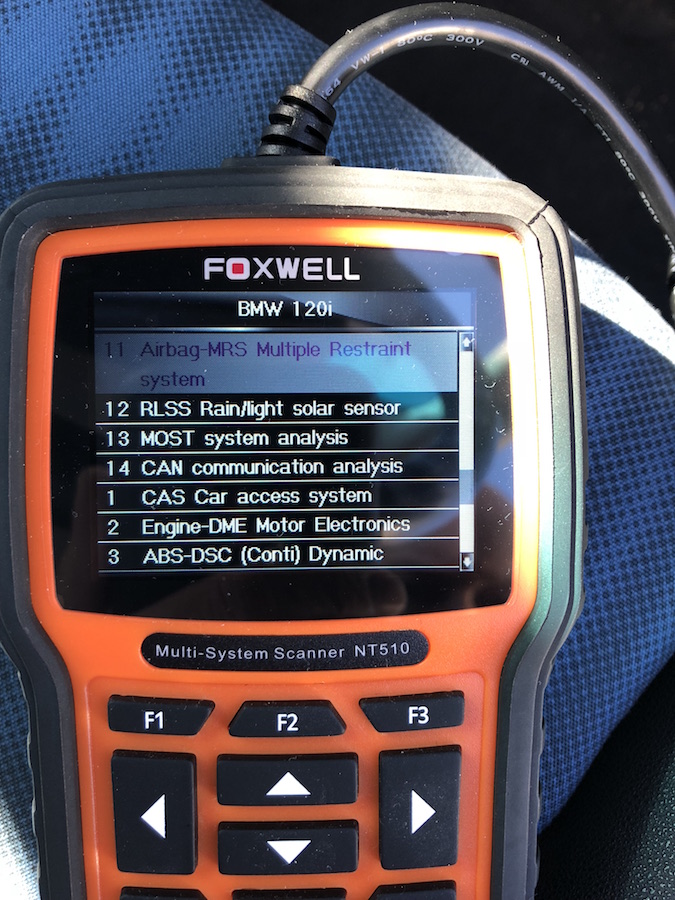

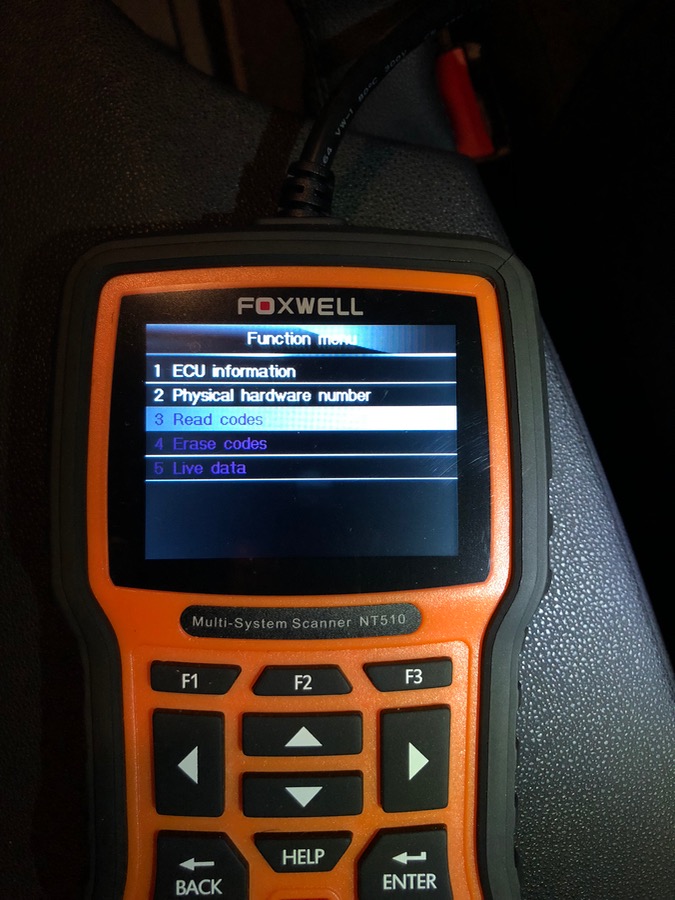

) I turned my attention to it again. The first thing I did was order a Foxwell NT510 OBD-II code scanner, so I could interrogate the car's computer and clear fault codes to see if problems were resolved.

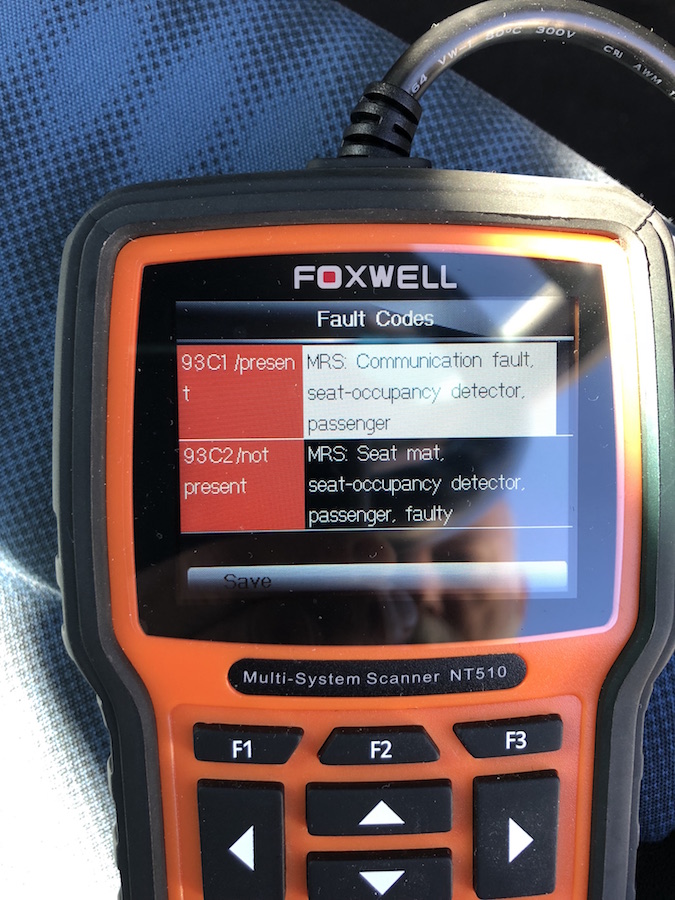

The going wasn't easy with my very basic POC 'Dick Smith' multimeter; not sensitive enough to test a few suspect SMDs I lifted from the board. I soldered them back in place, effectively but untidily, though with no improvement. Each time I plugged the sensor in under the passenger seat and then pushed the key in my BMW would go 'Bing!' and display the now familiar Malfunction Indicator Lights. The code scanner advised of two problems; a communication fault and a faulty passenger seat occupancy sensor mat. Hmmm.

I decided a reflow might help so removed the connected wires and the Force Sensing Resistor mat and warmed the board on our clothes iron, balanced upside-down. It didn't take long before the three wonky components I'd worked on settled into place. One was the smaller of the three canister capacitors, 47jFC, which sustained a broken leg during the initial stripping of the board's silicon gel encasing. Next time I'll start with the iron on a lower setting. The board looked somewhat cooked after this treatment.

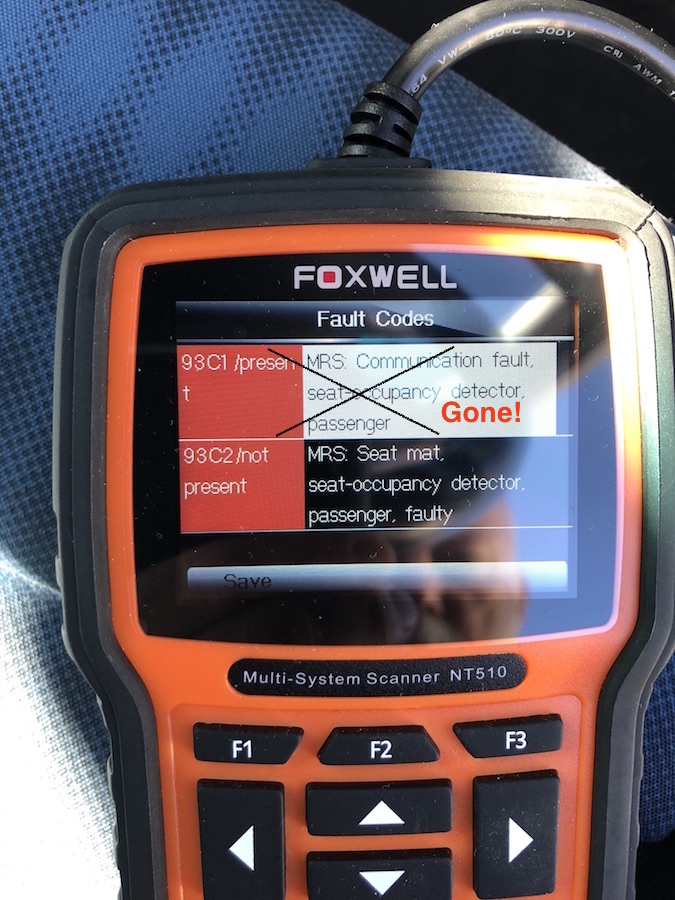

With the wires and pressure mat back in place and a stand-in 5.6V Zener diode soldered on (thank you Niklas) I ran another test in the car and was encouraged when the computer decided it could now talk properly with the sensor. I was down to only one fault code - a small success.

At about this point wifey kindly proposed that my determination warranted reward with a Fluke 289.

Boy oh boy has that been handy. If I did at some stage mention that it was probably repeat application of pressure from her petite posterior that broke the sensor in the first place ... well, that might have cost me an upgrade.

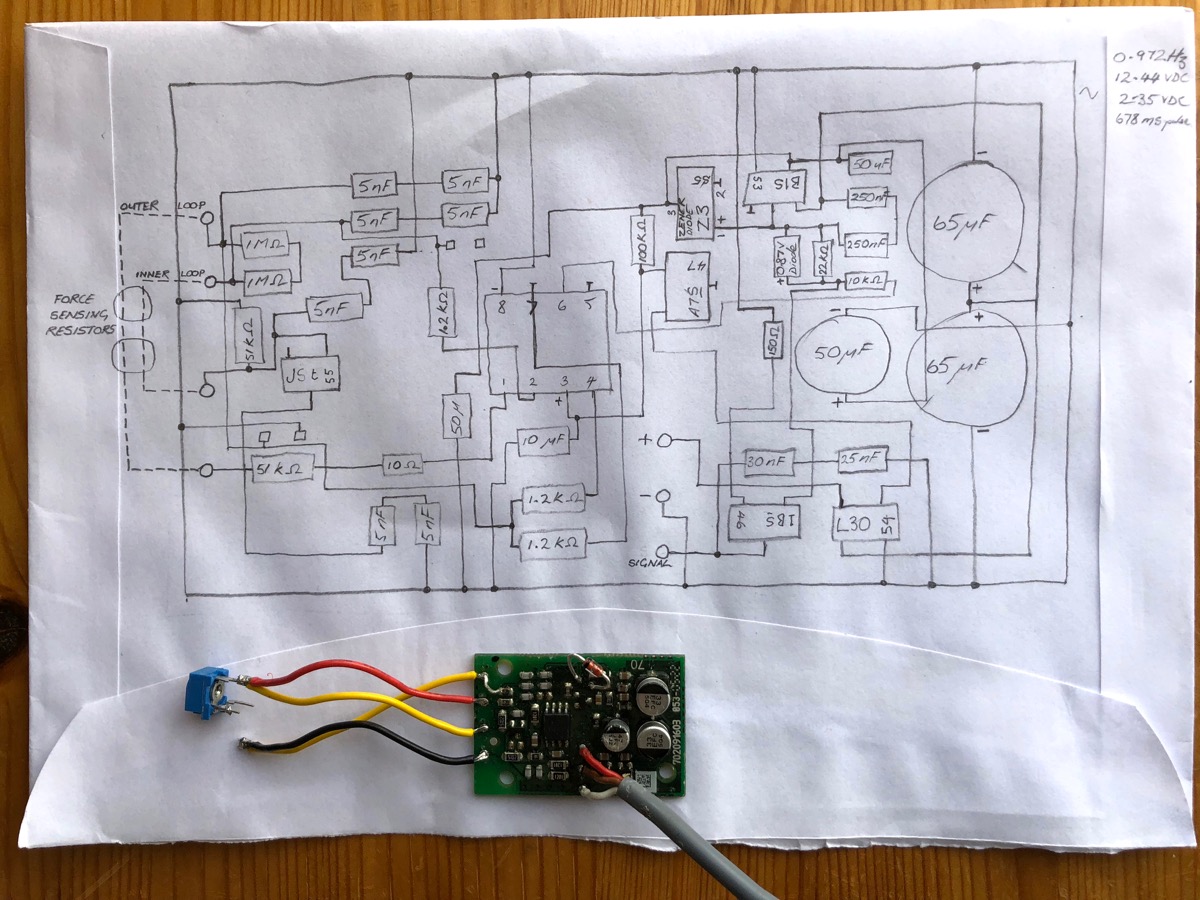

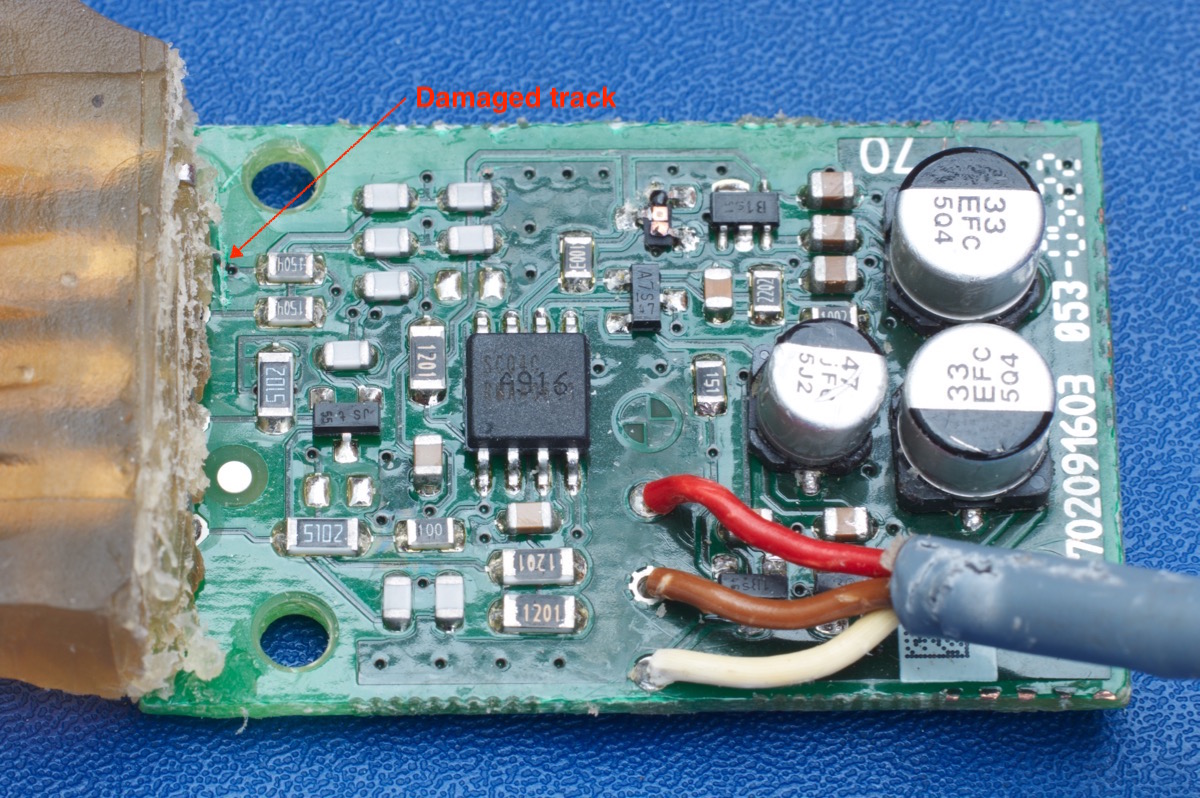

I followed SMdude's advice and drew up a schematic, on the back of an envelope. The 289's multi-range continuity function was particularly helpful with this. The Fluke's sensitivity also allowed me to assess that all of the components were working, seemingly. When I was cross-checking my schematic against the board yesterday morning I found that a scratched track which had tested OK before (with my old, cheapo meter) was in fact open. The screwdriver damage that nali noticed, at top left in the picture below the schematic, might have been hanging on by a thread at first or might have been broken all along. I soldered a temporary bridge in place and looked forward to running another test in the car, upon its return with wifey in the evening. That test was done in the cold, dark driveway last night and with the old fault codes cleared, the car did not go 'Bing!'.

Now that I know the board has life in it and that the extent of the Safety Restraint System fault is limited to it alone, I'll continue with making a tidy and complete repair and assess its suitability for installation back into the seat. A problem with these sensors is that there isn't an easy way, if at all, to determine what a working sensor is telling the ECU with respect to seat occupancy status. If the sensor serves up a 'no passenger' signal, the passenger airbag might not go off when it ought to. Crash dynamics and vehicle programming are variables. This problem would not be completely eliminated by installing a new replacement sensor/seat mat. False negatives would still go undetected. The point of these passenger seat occupancy sensors is two-fold: to reduce repair costs after lower level accidents by not firing the passenger seat airbag if it's not needed; and, in the situation where mum or dad is driving around the parking lot with junior standing in the footwell and leaning on the dash, to avoid blowing the child out the back window. It's happened.

I'm rather pleased that I've avoided the expense of a maintenance action that might not have worked, by spending about twice as much as the replacement part alone on a quite wonderful multimeter and a really handy code scanner.

I might still buy a new sensor mat, but at least I'll know it's the correct repair.

In case anyone finds this thread by searching, some details about this passenger seat occupancy sensor mat from my 2005 BMW 120i E87 are:

- the 8 pin IC in the middle of the board generates an oscillating wave of 0.972Hz and approximately 12V amplitude. I've concluded that the car's ECU looks for this signal to determine that the sensor is present. It also checks for the integrity of the sensor's Force Sensing Resistor mat itself.

- the sensor mat comprises inner and outer loops of traces interconnected by Force Sensing Resistors. My wife's bottom causes the resistance between the inner and outer loops to change from infinite with no force applied to approximately 200kOhm with her 47kg of weight sat on it. During my testing I used a 216kOhm trim pot to simulate my wife's bum.

- my BMW dealer charges AUD$498 for a new mat and probably twice that for installation.

- the Zener diode I needed to get my passenger seat occupancy sensor working cost 65 cents. A proper SMD one might cost a bit less though.

Regards, Rick.