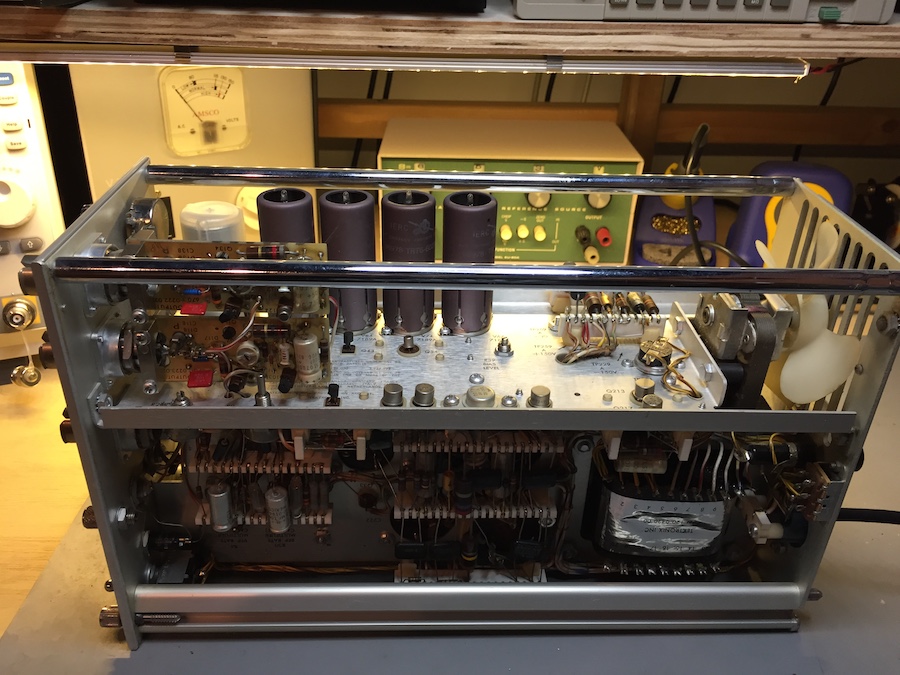

I continue to work my way through the stack of Tektronix gear I've picked up over the last year. A week ago I started working on a type 106 square wave generator. The 106 is interesting because it will put out a 120Vpp square wave, making it handy for calibrating scopes and such.

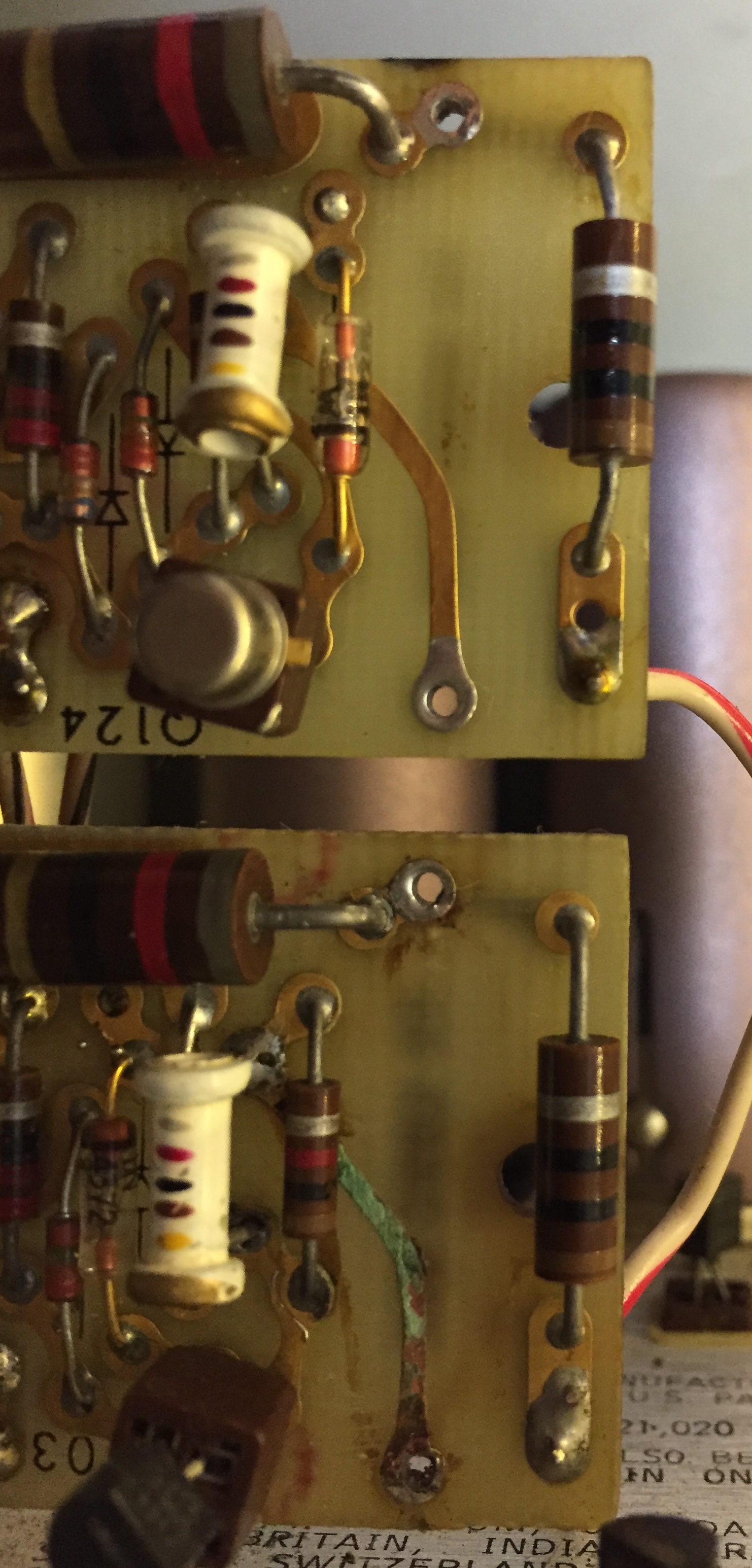

A visual inspection revealed four bad electrolytic capacitors. Two were bypass caps on the +/- 10V rails and two were DC blocking caps on the input side of the output buffer amps. That bad blocking cap explained why there was no output on on one channel. Here's what they looked like:

And the damage done to one of the boards. The trace was still good after I cleaned all the capacitor innards from the board:

This is an old piece of gear and uses ceramic terminal strips with silver plated notches. On the back of the unit is a small roll of silver solder for making repairs; this came in handy when replacing the caps.

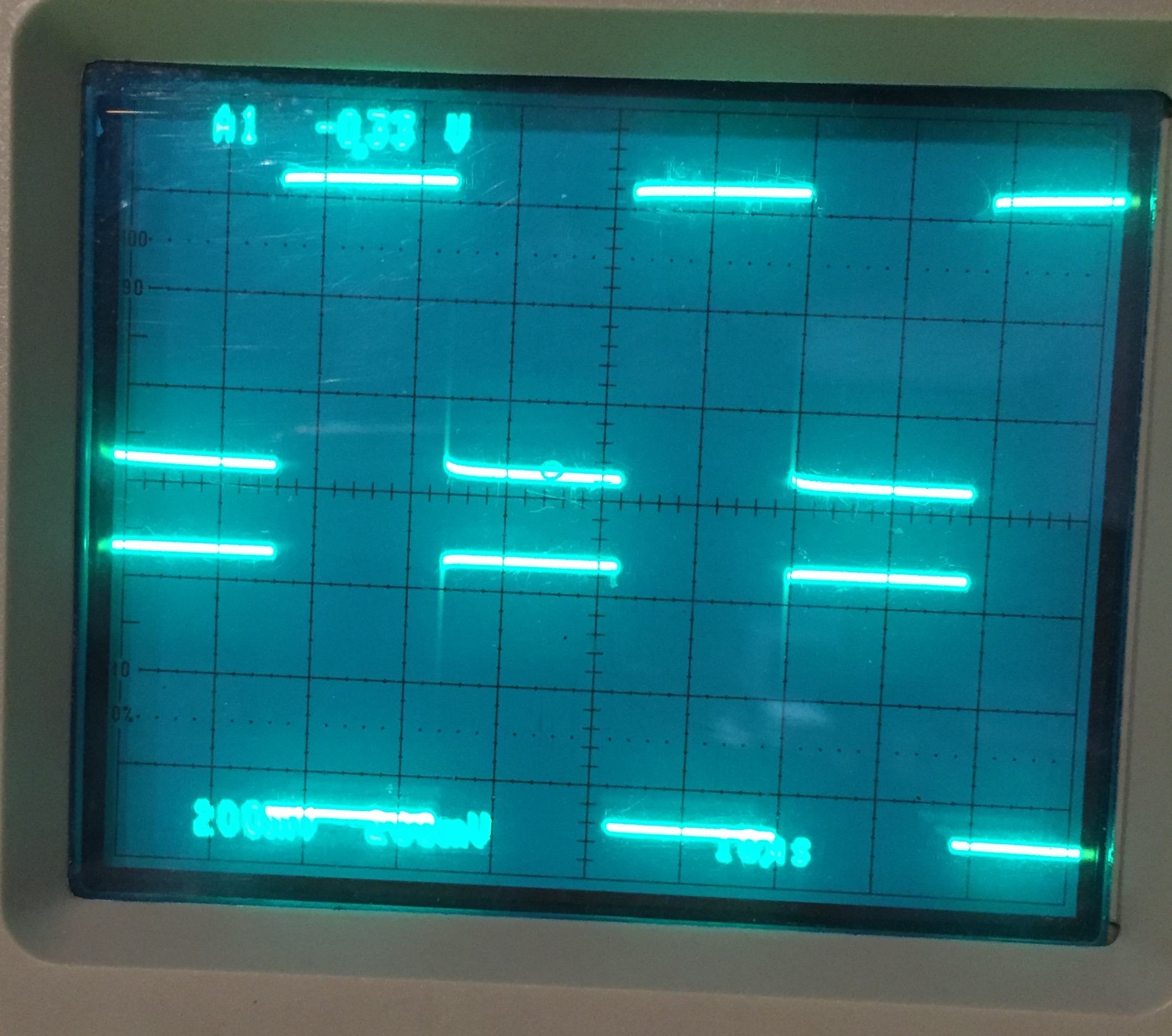

With these repairs made, I did a quick power up test. Joy was experienced:

The 106 was putting out decent square waves on both the "high amplitude" output and the fast rise and fast fall time outputs. A quick run through the manual's performance check procedure indicated that all the functions worked, so doing the factory calibration was next up.

All was going well. The power supply rails were all in spec, after making minor adjustments, both the variable frequency and amplitude circuits worked as expected. I figured I'd be done and buttoning the box up in a hour or two.

Then...

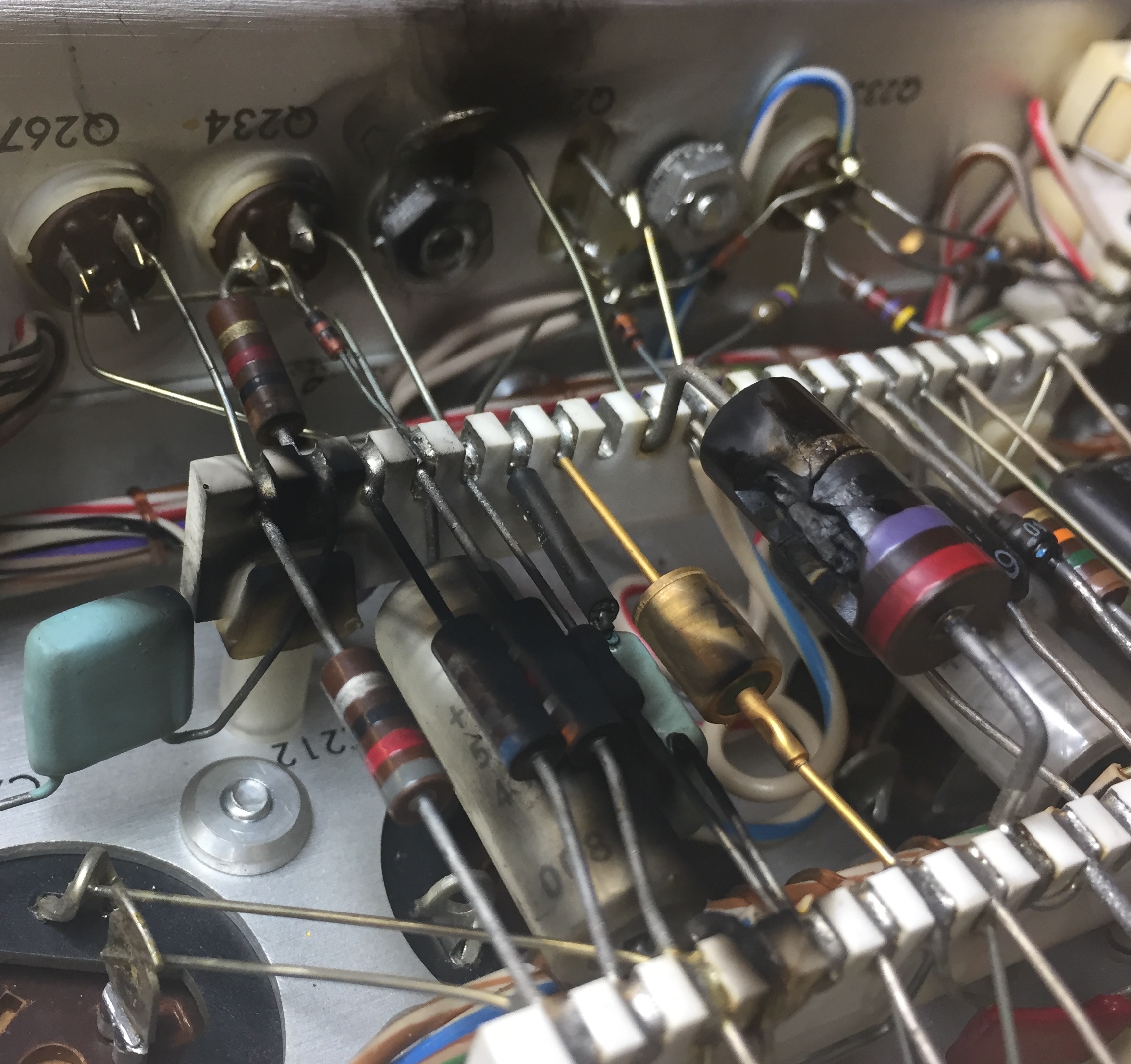

I let the

smoke out while checking for ripple on the 150V rails. I am still not quite sure what I did but whatever it was pushed a whole bunch of current through a 2W resistor and a power transistor.

The flames were quite impressive. I thought I might have done serious damage, so I checked all the transistors and diodes in the circuit path. Luckily it appears that I merely destroyed one resistor and one transistor, both of which are easy to replace.

actually, as I was writing this and looking at the schematic, there's one other transistor I need to test. It is is possible that shorted the +150V rail through the output transistor in that circuit into the -150V rail.

So this one is on hold. While I am waiting for parts, I will put the companion to the 106, the 067-0542-99, with a frequency wave of 1Hz to 1MHz and an output range of 20mV to 100Vpp.