Sorry to bump a somewhat old thread, but I wanted to write some concluding thoughts on the method, now that the project is near done.

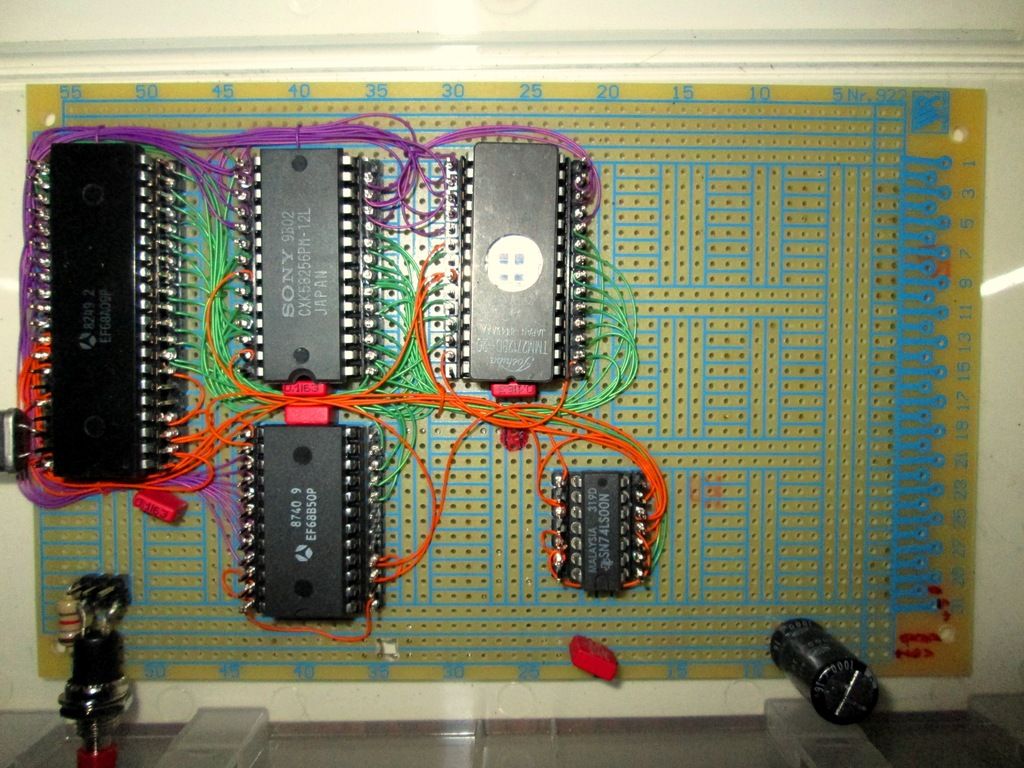

It can be done way neater than the original photo I posted (I think it's the first wire wrapped board I did), as the pic of the new board will show.

So far I've encountered some minor issues, but the benefits make it very worthwhile, I think.

Cons:

- Difficult to use modified wrapping (with some turns of insulated wire) - might just be my tool.

- Fits only two wrappings per pin, could use dual row headers if needed.

- Tight fit between IC socket and pin for the wrapping tool. when soldering in the headers, tilt them slightly outwards.

-

probably not as low contact resistance as a professional socket (not tested) - but it didn't have an impact on the circuit.

Pros:

- VERY VERY cheap. a 40 pin socket cost me around a dollar, headers and all. as opposed to 10-20 USD per 40 pin wire wrap socket.

- Low profile: only the fraction of height of a wire wrap socket

- Can be mounted on same side as IC, aids the layout and wrap process significantly.

- Socket and headers IDEAL for IC pattern prototype boards.

All in all, I'm pretty happy with it. You can get long pin headers, so you could essentially make pins the same length as wire wrap pins, but i kinda like the low profile of the circuit board.

Hope some will find this useful

--Christoffer