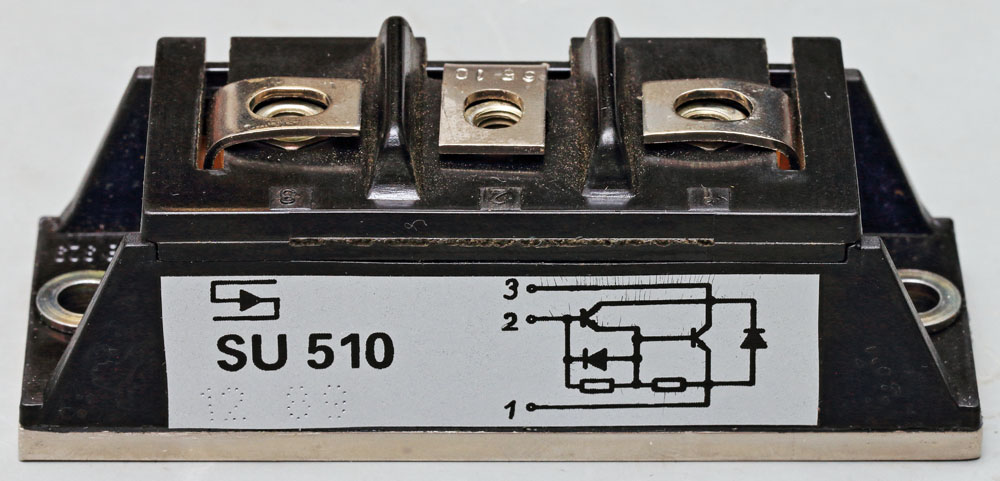

Let´s look at a big darlington built in the "Gleichrichterwerk Stahnsdorf": SU510

800V / 30A / 250W

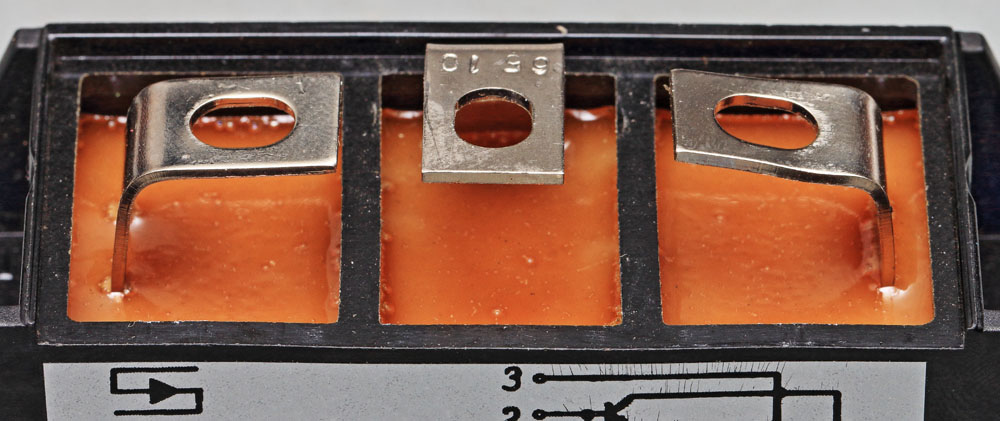

Without screws you can simply slide out the top cover.

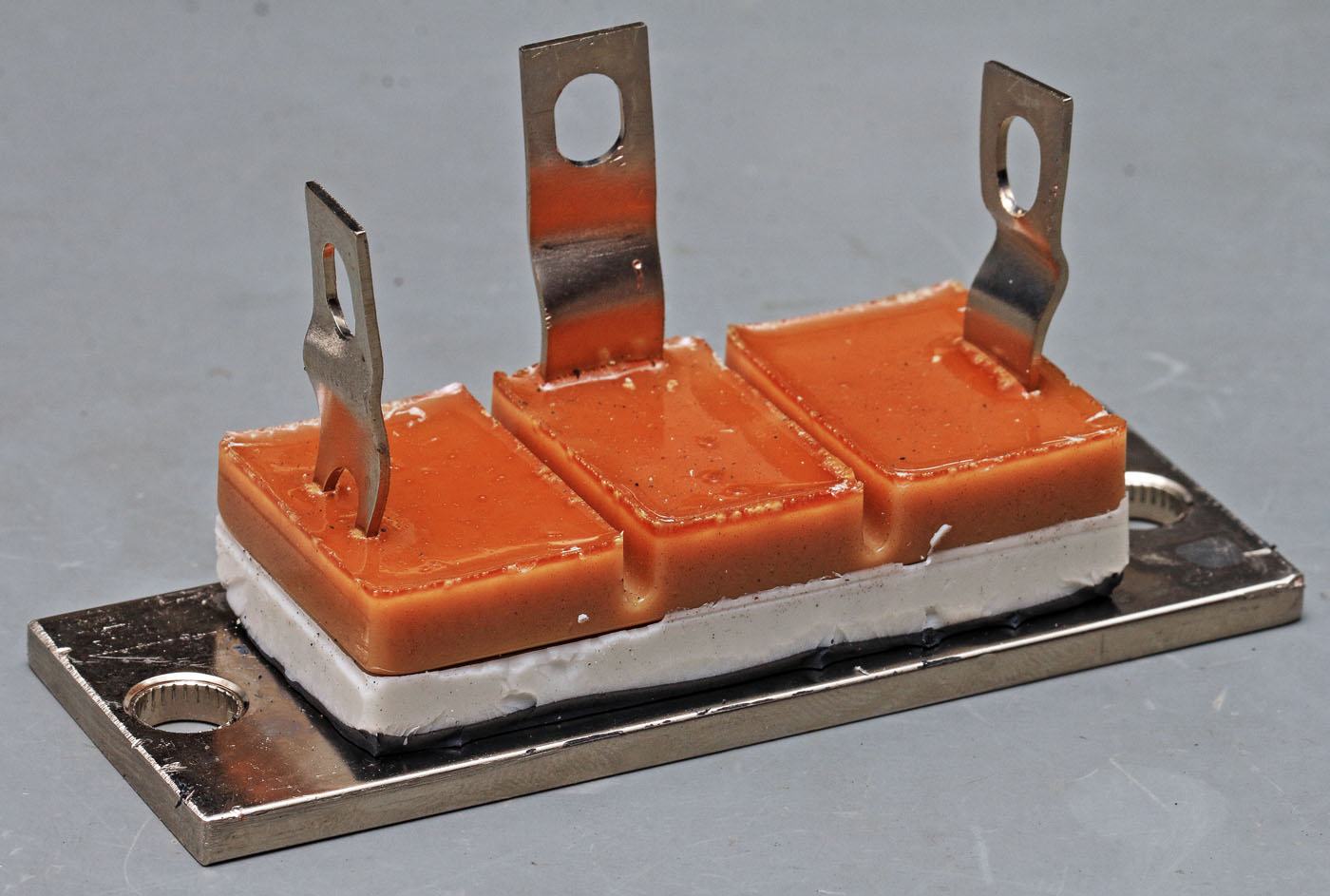

Under the black case there is a white silicone similar to "normal" silicone protecting the semiconductors.

On the bottom there is a thin black layer. I assume the black layer just had to hold the case during assembly and applying the white potting.

On top there is a brownish hard potting. Obviously this material protects the silicone since the top of the case is virtually open.

Cutting the metal sheet contacts you can remove the brown part. The silicone potting had to be removed with patience. On thin layers silicone remover can help.

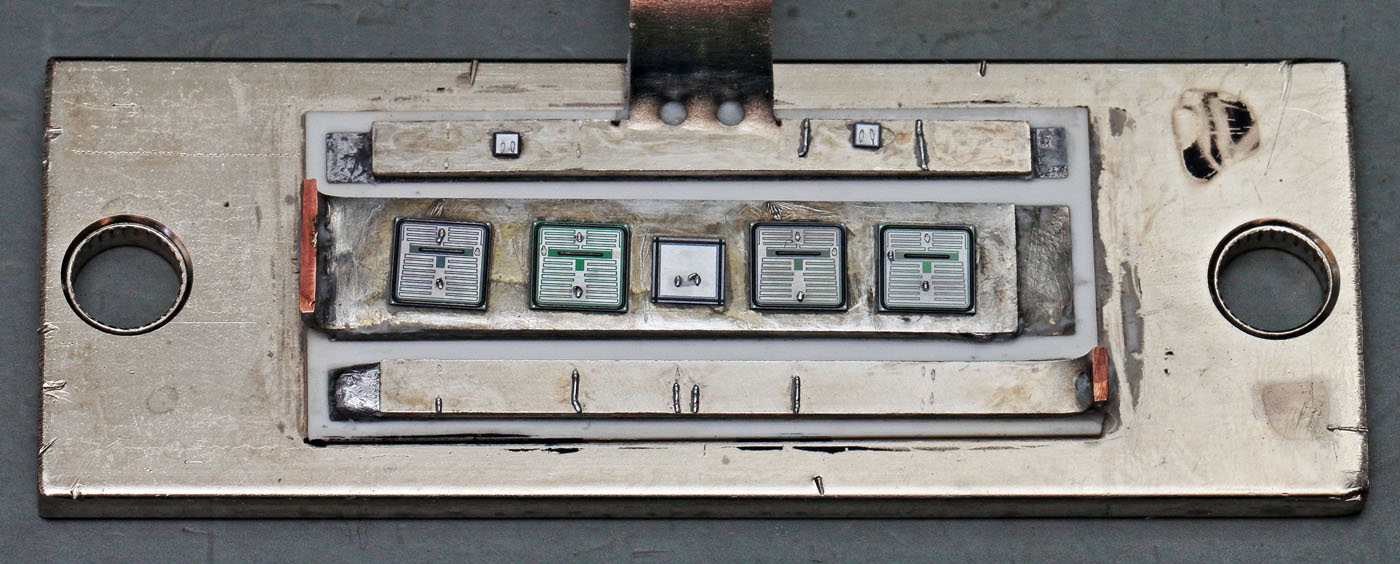

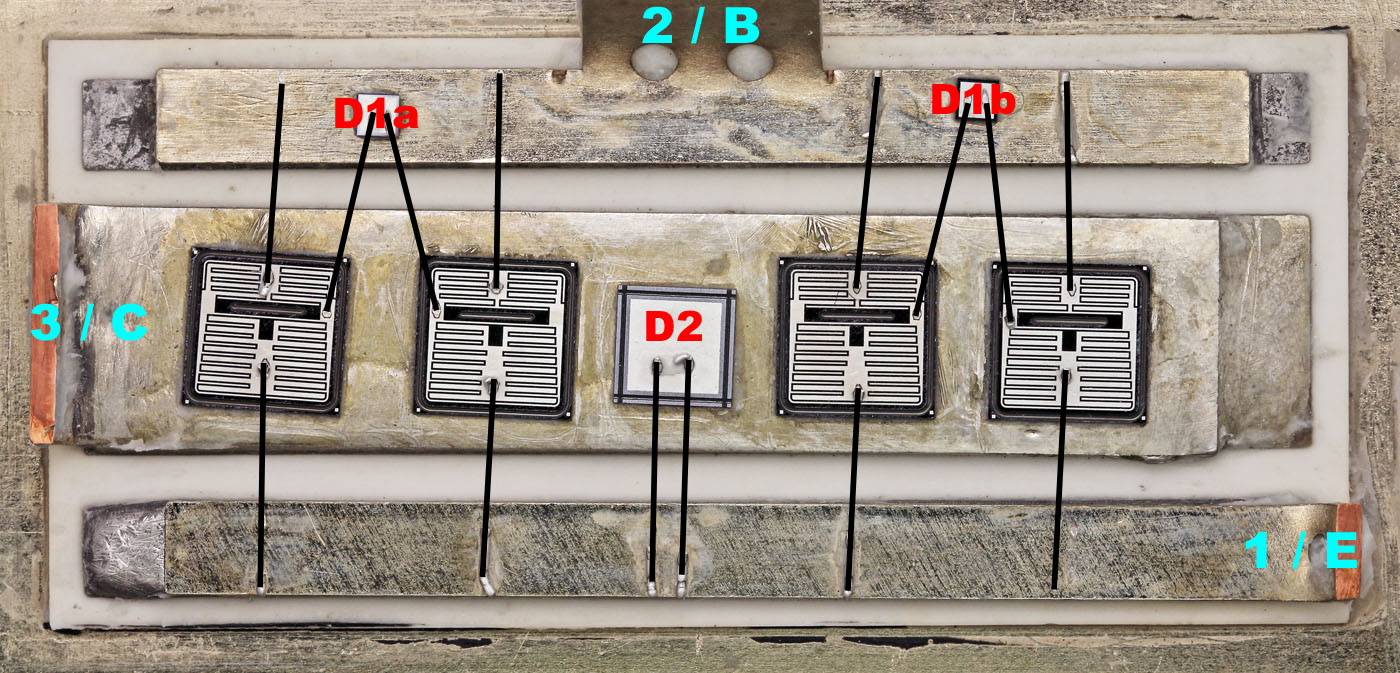

In the package there are four Darlington-Dies and a large freewheeling diode. Two small diodes are connected in parallel to the base emitter junction of the driver transistor for faster switch off.

The small diodes own only small structures at the edges because they don´t have to withstand high voltages.

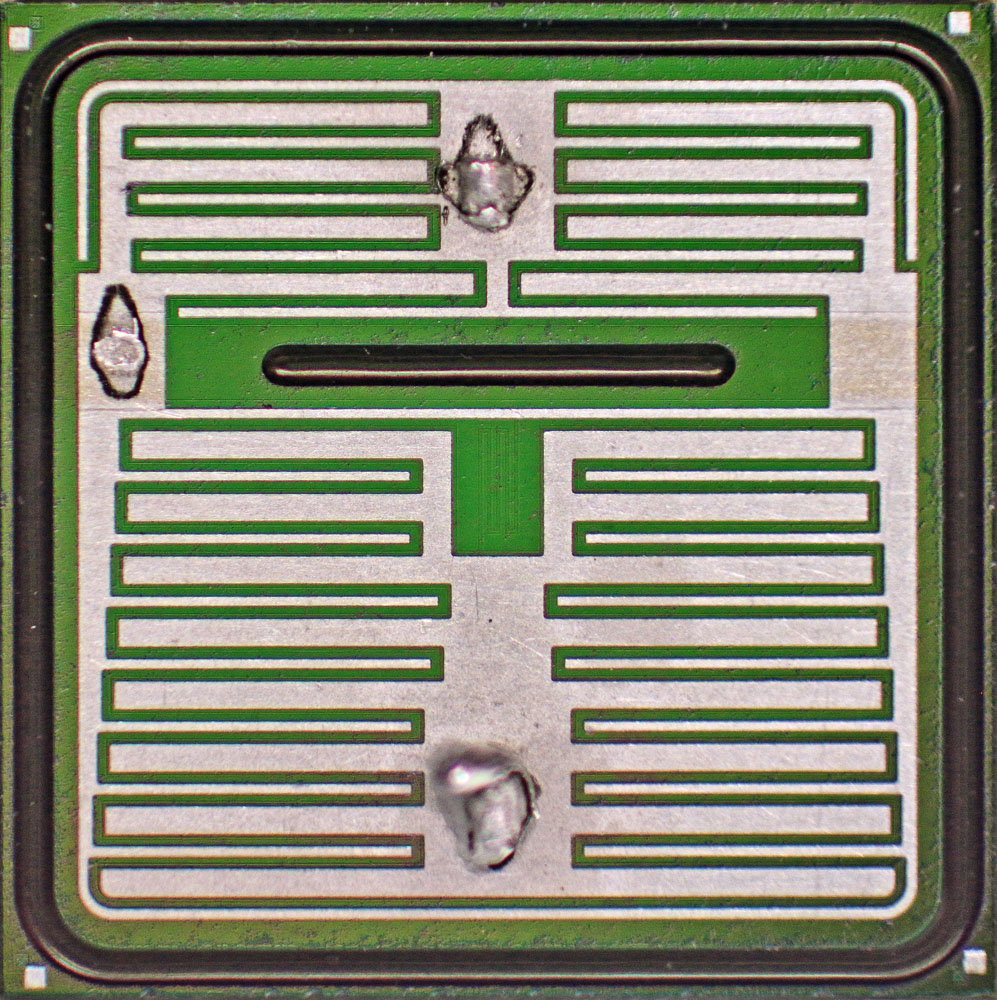

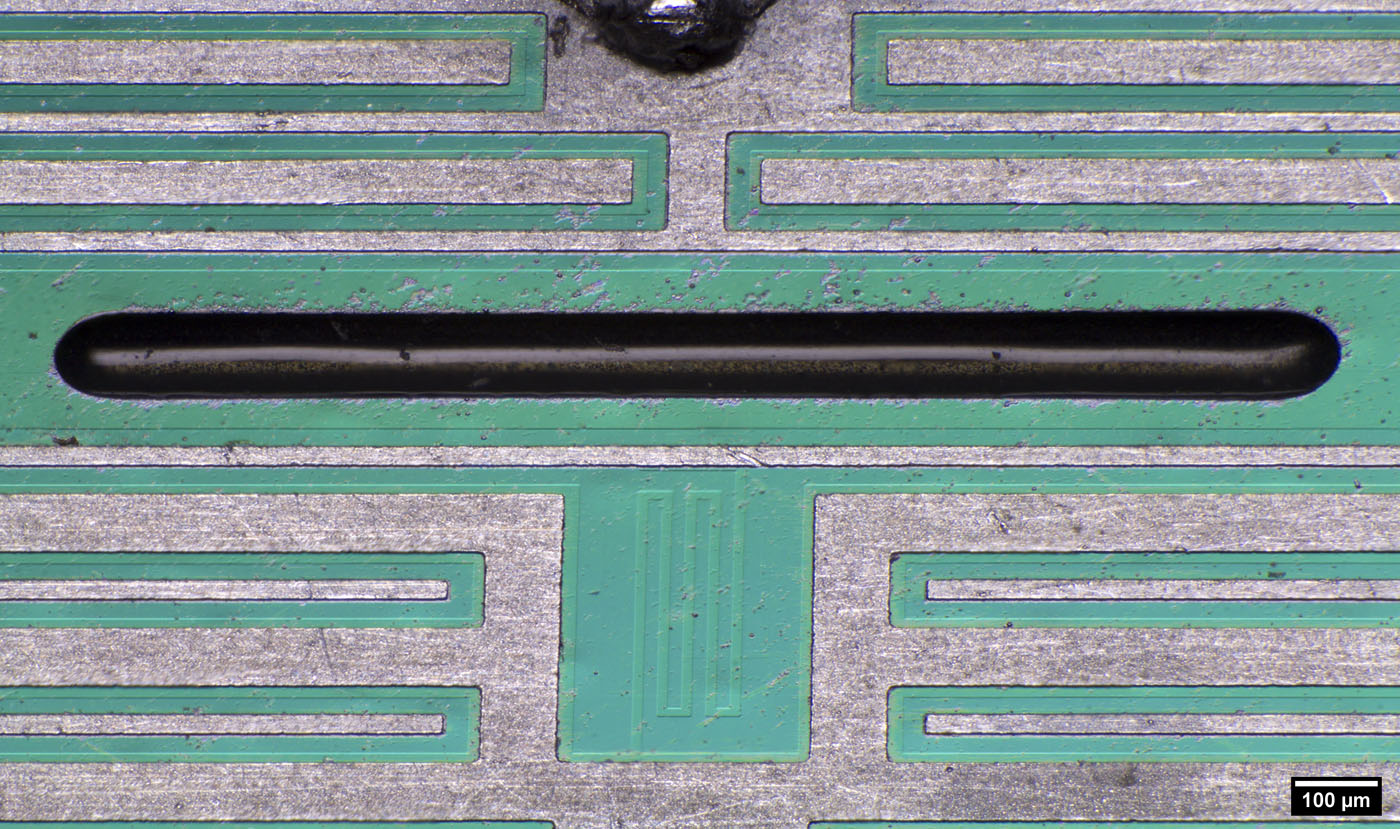

The darlington transistor die is quite interesting. In the upper area there is the driver transistor. In the lower area there is the power transistor. Between these transistors they etched a trench. I wonder what exactly is the purpose of this trench. It somehow has to isolate the two transistors.

In the middle of the die you can see the resistor connected between base and emitter of the power transistor.

The freewheeling diode has to withstand the full voltage and because of that has etched edges to reduce leakage current.

More pictures here:

https://richis-lab.de/Bipolar24.htm