Will the documentation that comes with the unit contain a schematic and brief theory of operation please ?

Noted, I'll include that.

This normally requires an expensive high quality crimper.

I've ordered one of these, they are not as expensive as you might think. They develop huge force and should make reliable, gas-tight crimps.

Great little device you've made

I'm just curious, would it help to use flux? Common solder one or plumber type? Sure it will just burn into smoke rapidly, but will the surface finish/oxidation, and color look better? Any difference in the quality of the weld?

Thanks

Its welding not soldering, the temperatures are way higher here, maybe 1000degC. I think that flux will just vaporize or burn.

The welds actually look better than many of those which I showed in the videos. That was letting you participate in me experimenting, and of course to discover the limits. A typical weld of 0.1mm nickel strip to an 18650 cell typically does not produce any coloring.

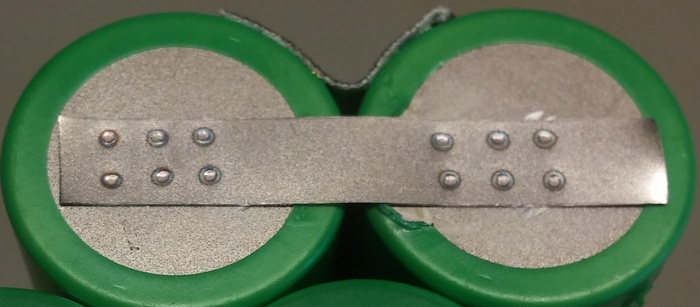

I just made these welds on a dead battery to show how a regular weld looks like: this is

0.2mm 0.1mm nickel strip, the energy is set to 30J. It can probably still be lowered.

EDIT2: Okay, I'll have to take back everything that I said about using flux. The below welds are with

0.2mm nickel strips, and you can see the coloring which cannot be prevented when doing it as usual. Except both leftmost welds per cell, where I added a drop of flux! Awesome, I can definitely recommend that to everyone! The used flux was Chipquik SMD291.