It seems that I have to create a DAC-topic.

Let´s start with the Burr Brown DAC709!

"U.K."

The datasheet gives you a lot of specifications:

Linearity Error: +/- 0,0015 %

Differential Linearity Error: +/- 0,003 %

Gain Error: +/- 0,07 %

Zero Error: +/- 0,05 %

Power Supply Sensitivity Vcc: +/- 0,0015 %/%Vcc

Power Supply Sensitivity Vdd: +/- 0,0001 %/%Vdd

Total Error Over Temp Range: +/- 0,08 %

Total Full Scale Drift: +/- 10 ppm/°C

Gain Drift: +/- 10 ppm/°C

Zero Drift: +/- 2,5 ppm/°C

Differential Linearity Drift: max + 0,009 / - 0,006 %

Linearity Error: max +/- 0,006 %

Settling Time (to +/-0,003%; voltage output): 4 µs

Slew Rate: 10 V/µs

Settling Time (to +/-0,003%; current output in 10Ω to 100Ω): 350 ns

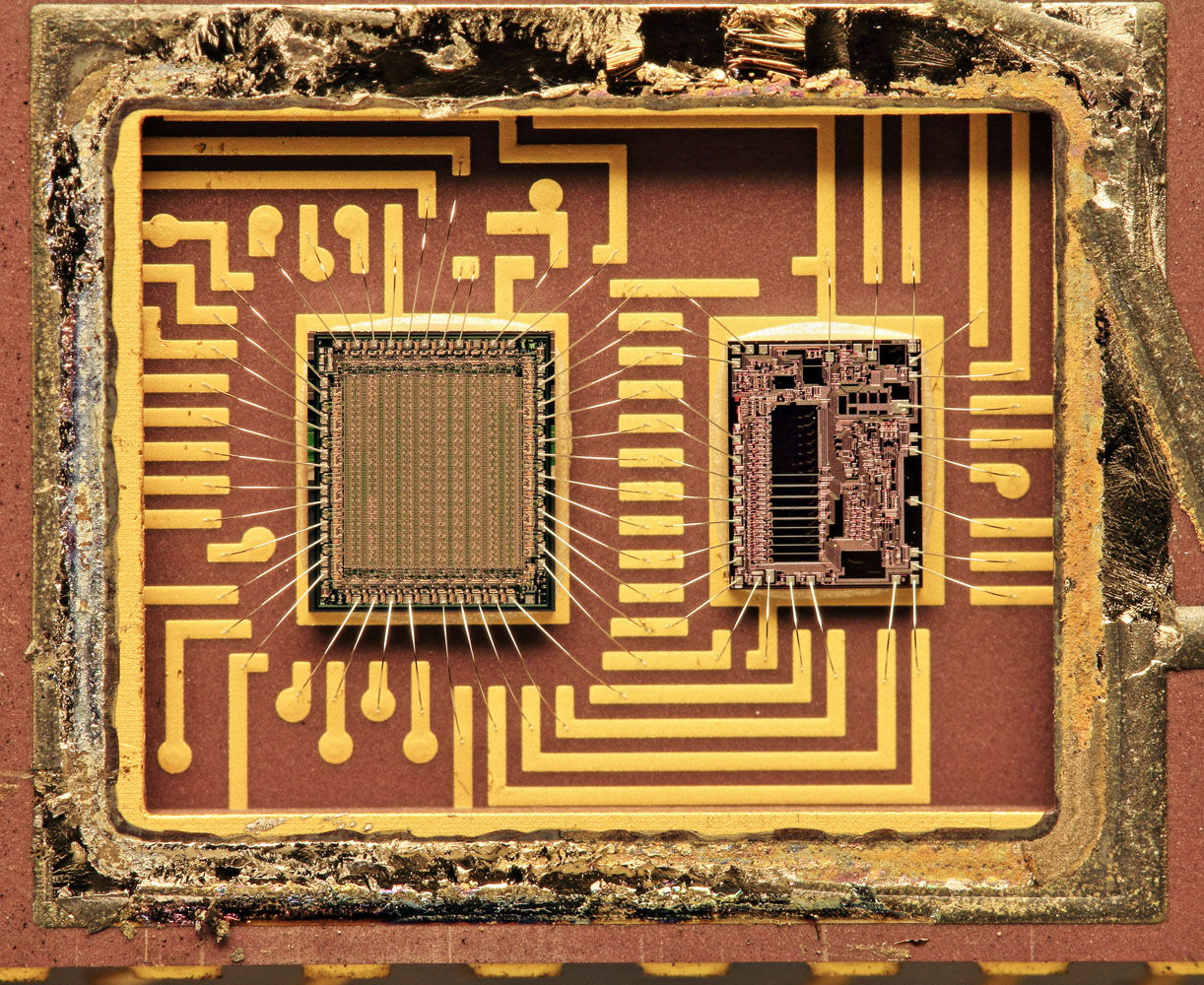

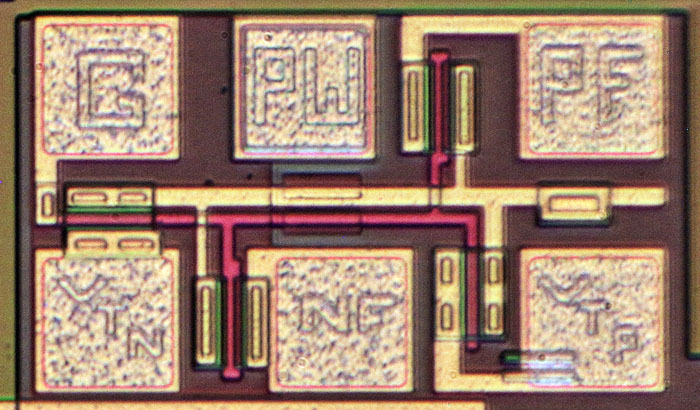

BB used two dies so they didn´t have to integrate the logic on the same die as the analog part which probably would have degraded the performance of the analog part.

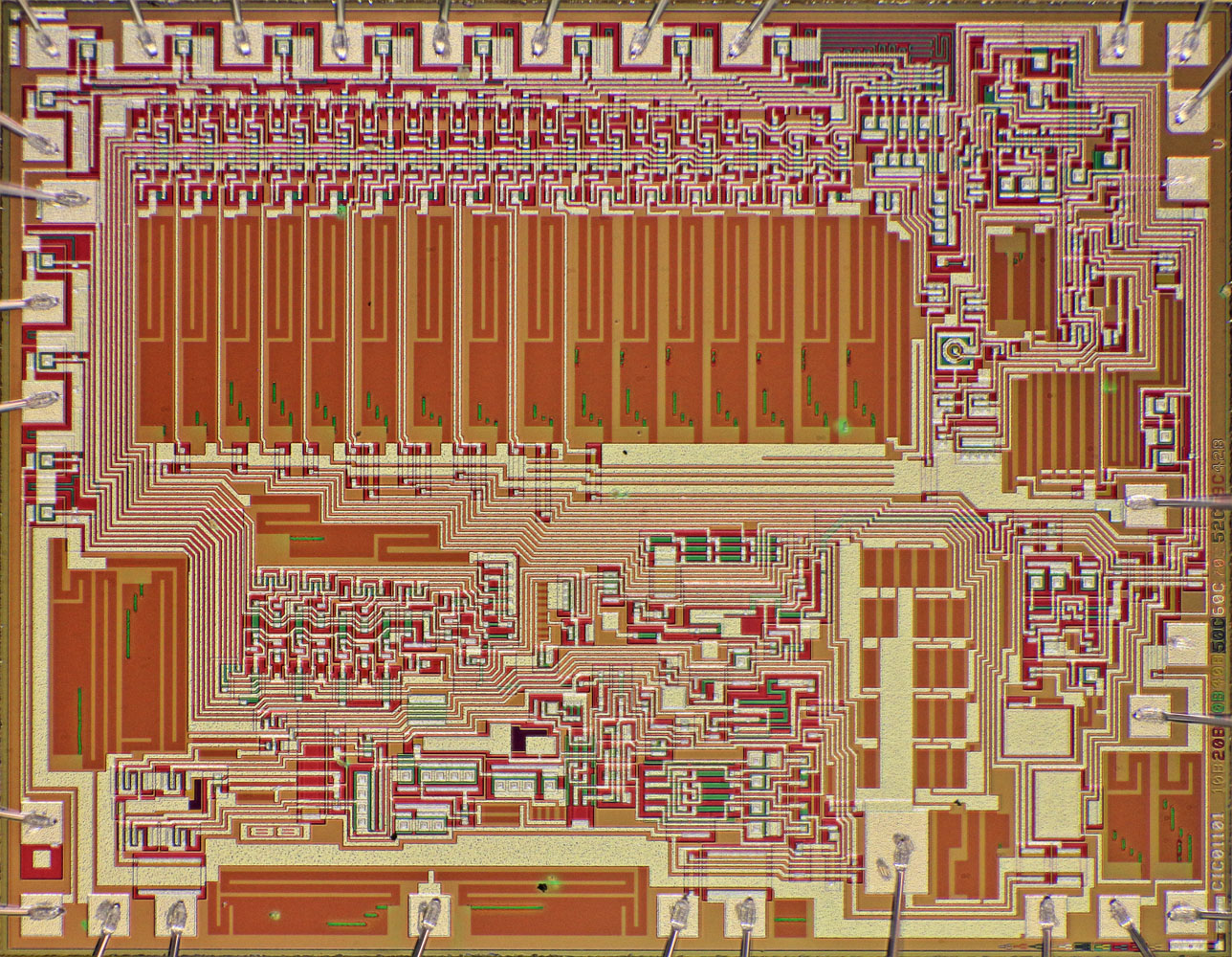

BTW: The Package has two interconnection layers.

I think BB was able to configure the logic die so it acts as a DAC707, a DAC708 or a DAC709.

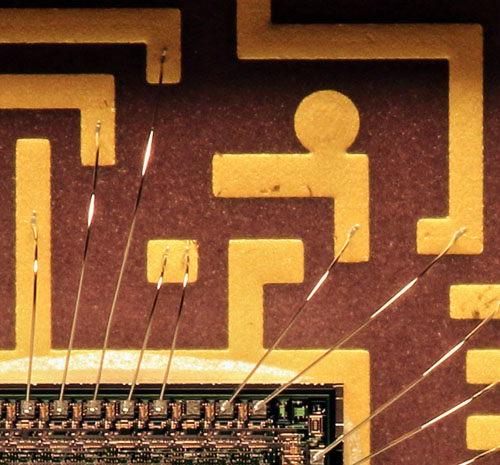

The two bondwires connected over an isolated square are promising candidates.

That´s an big old gatearray!

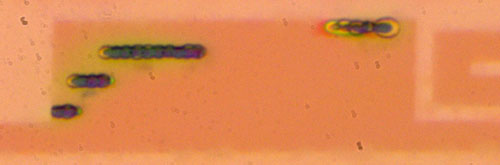

Nice test structures!

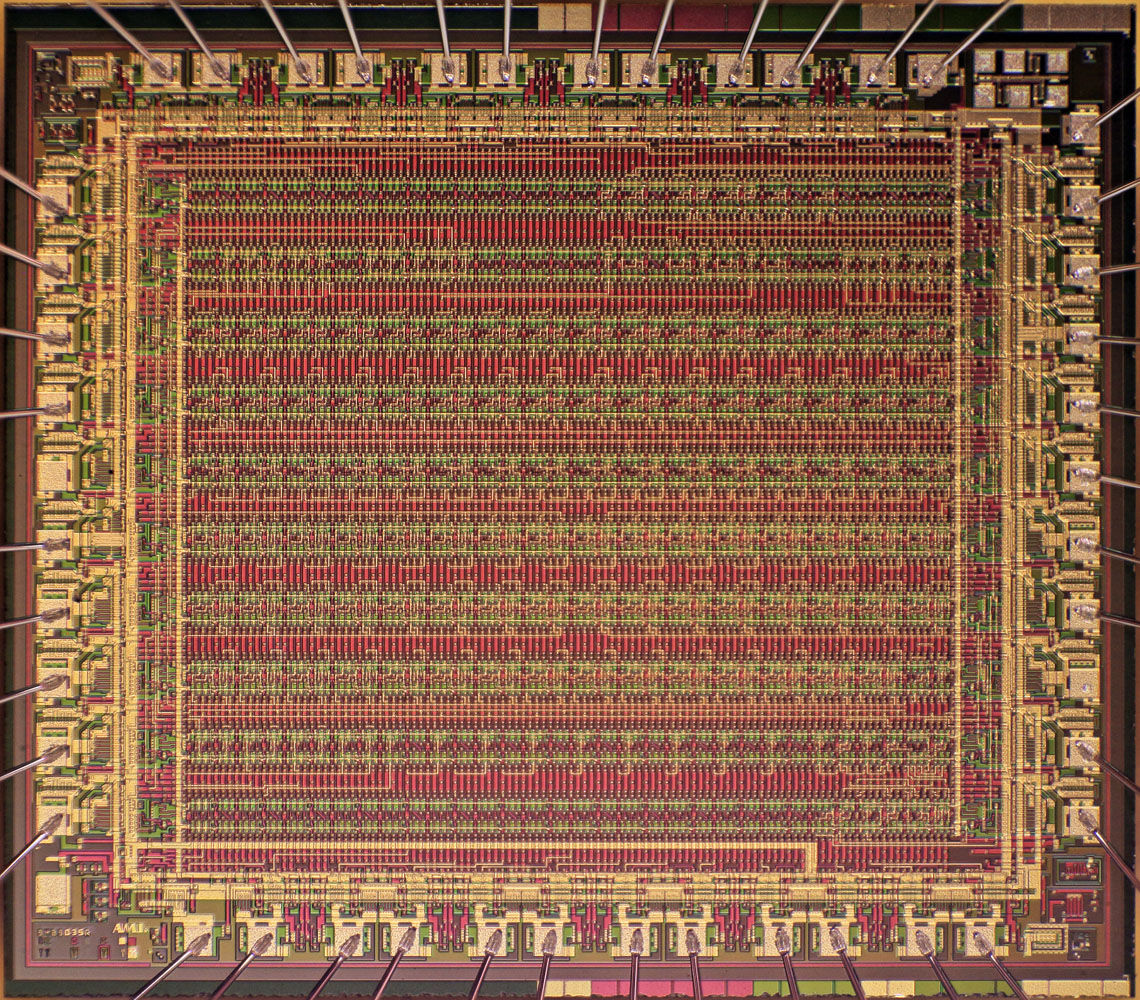

The DAC itself.

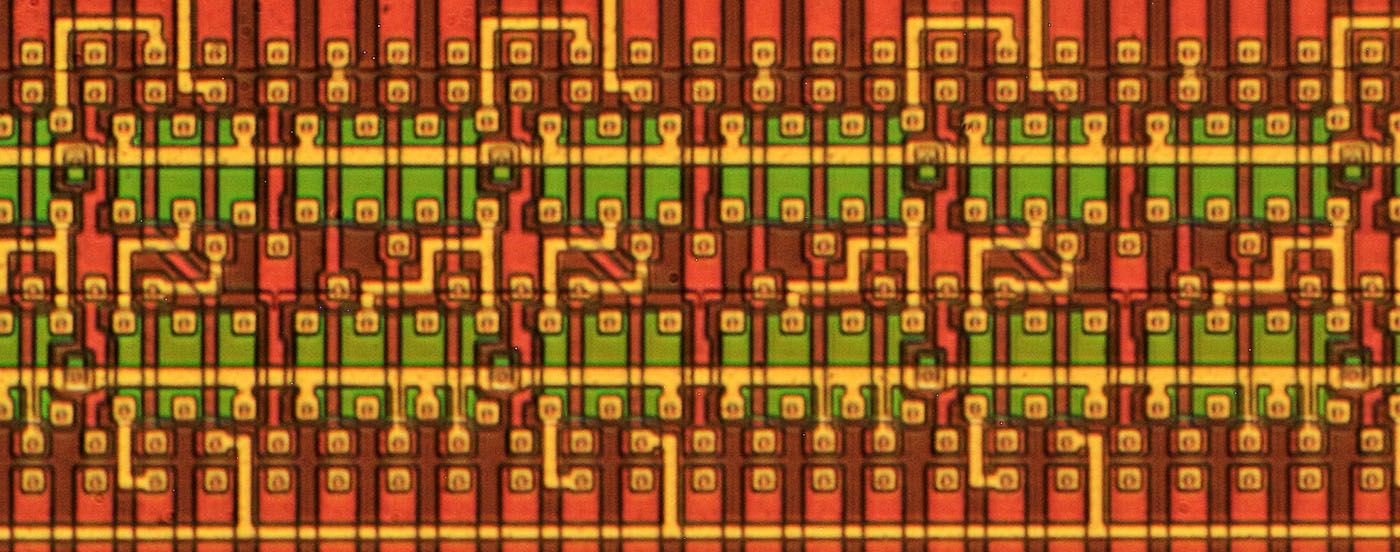

Resistor, Laser, Resistor, Laser, Resistor, Laser,...

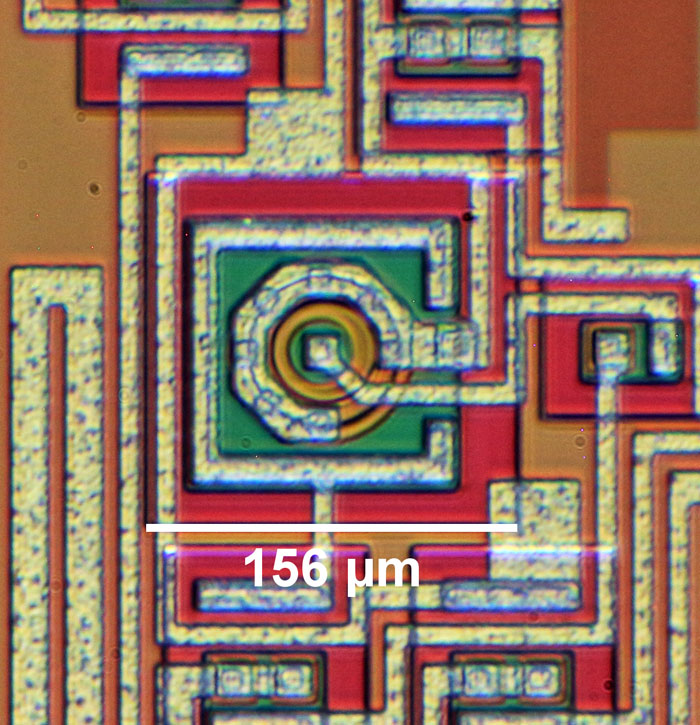

Buried zener! Yeah!

Some more pictures here:

https://richis-lab.de/DAC01.htm