The bandgap reference is based on the well-known principle described in more detail with the AD1403 (

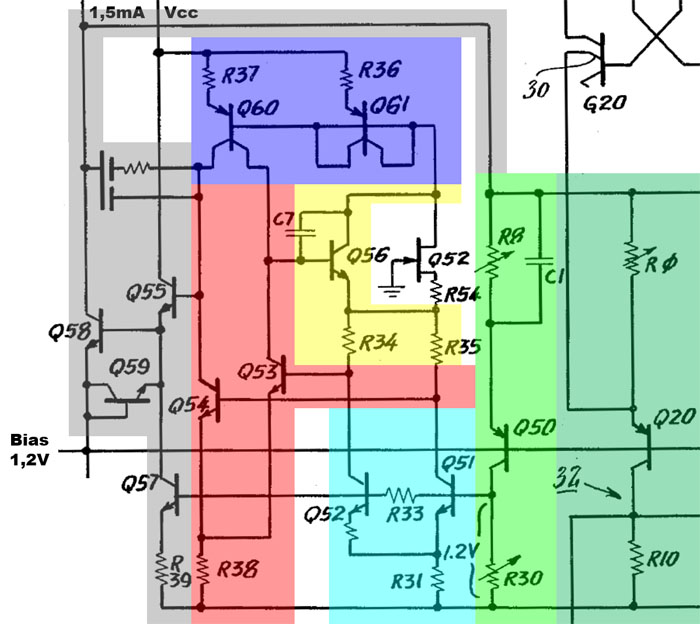

https://www.richis-lab.de/REF16.htm). At first sight, however, the circuit is a bit confusing. The core is formed by the transistors Q51/Q52 (cyan). Depending on the currents in the two paths, the transistors Q53/Q54 are driven differently (red). The two transistors are supplied via the current mirror Q60/Q61 (blue), which uses the sum current of the bandgap cell as reference current.

Via the gray path, the potential of the reference current source (light green) is adjusted so that 1,2V is applied to the base of the bandgap reference. If their emitter resistors are set correctly, this voltage is very temperature stable. The following current sources of the DAC (dark green) operate with the potentials of the reference current source.

Capacitance C1 ensures stable operation, as do the capacitors in the gray output stage. Q55 represents a driver, which works with the current sink Q57, which is based on the bandgap reference. In the output stage, transistor Q58 operates with a 1,5mA current source.

The current through the bandgap cell is controlled by Q56 (yellow). The JFET Q52 ensures a clean start-up.

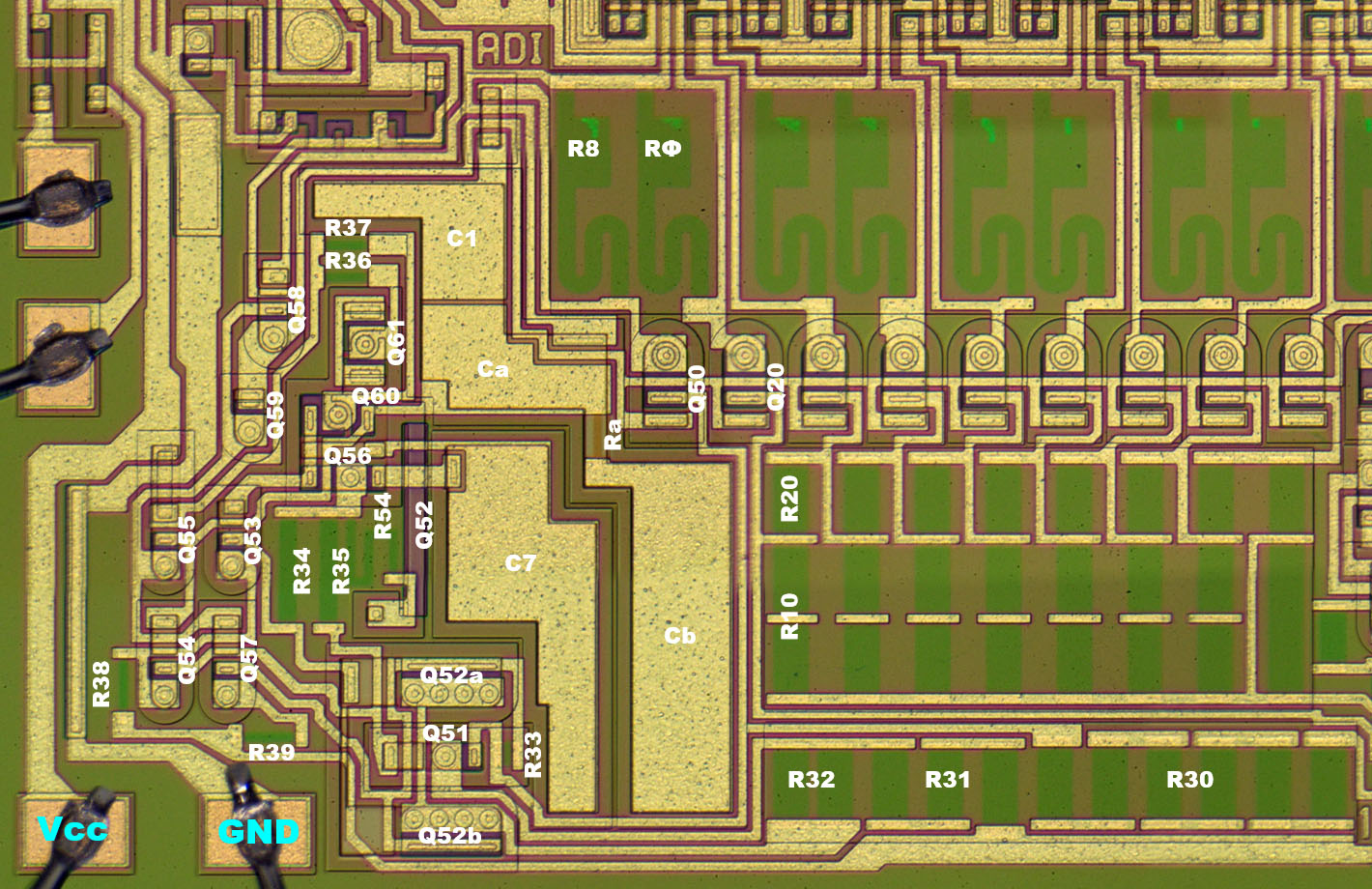

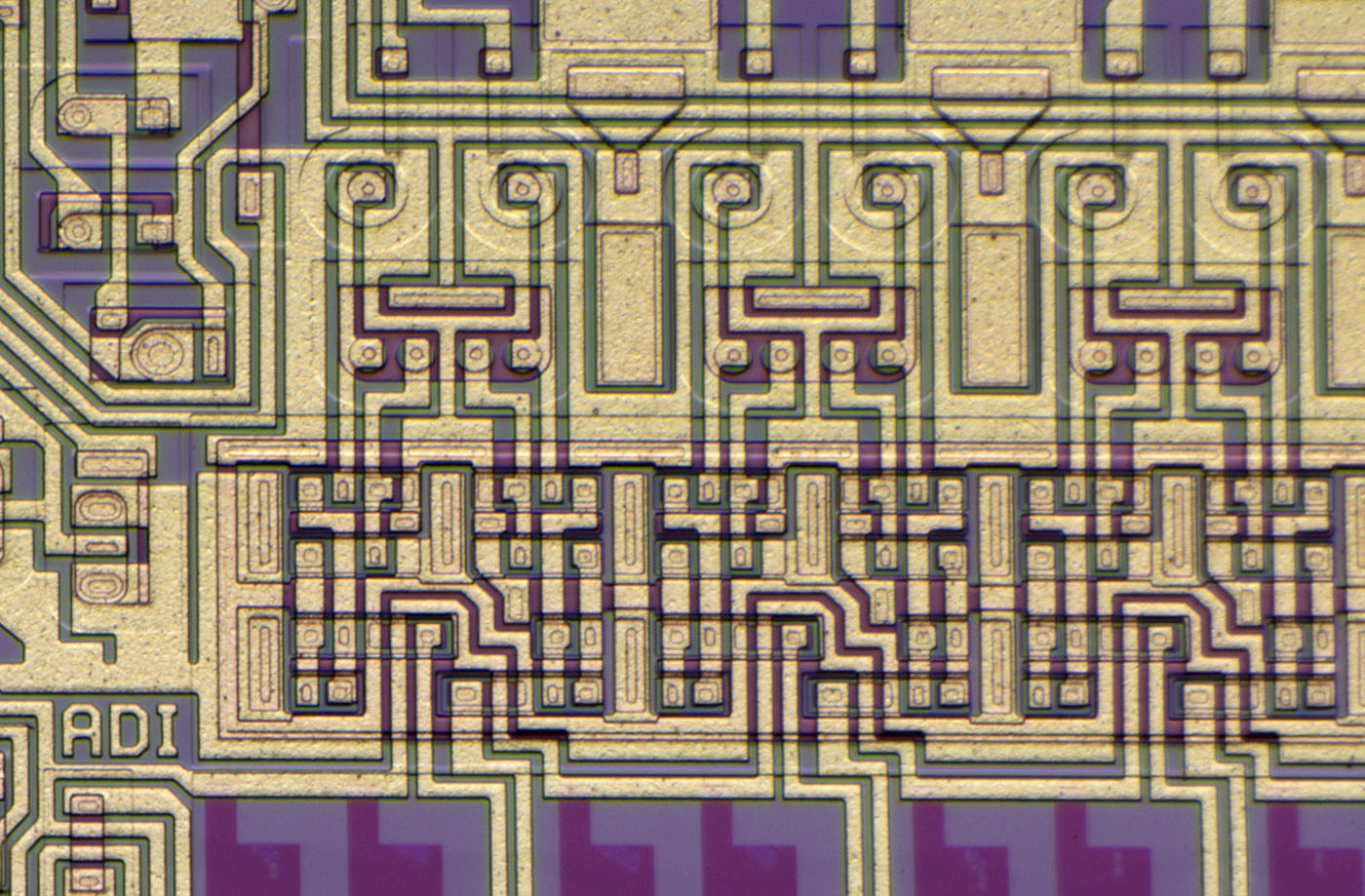

With the reference particularly noticeable are the large capacitors that provide the necessary stability.

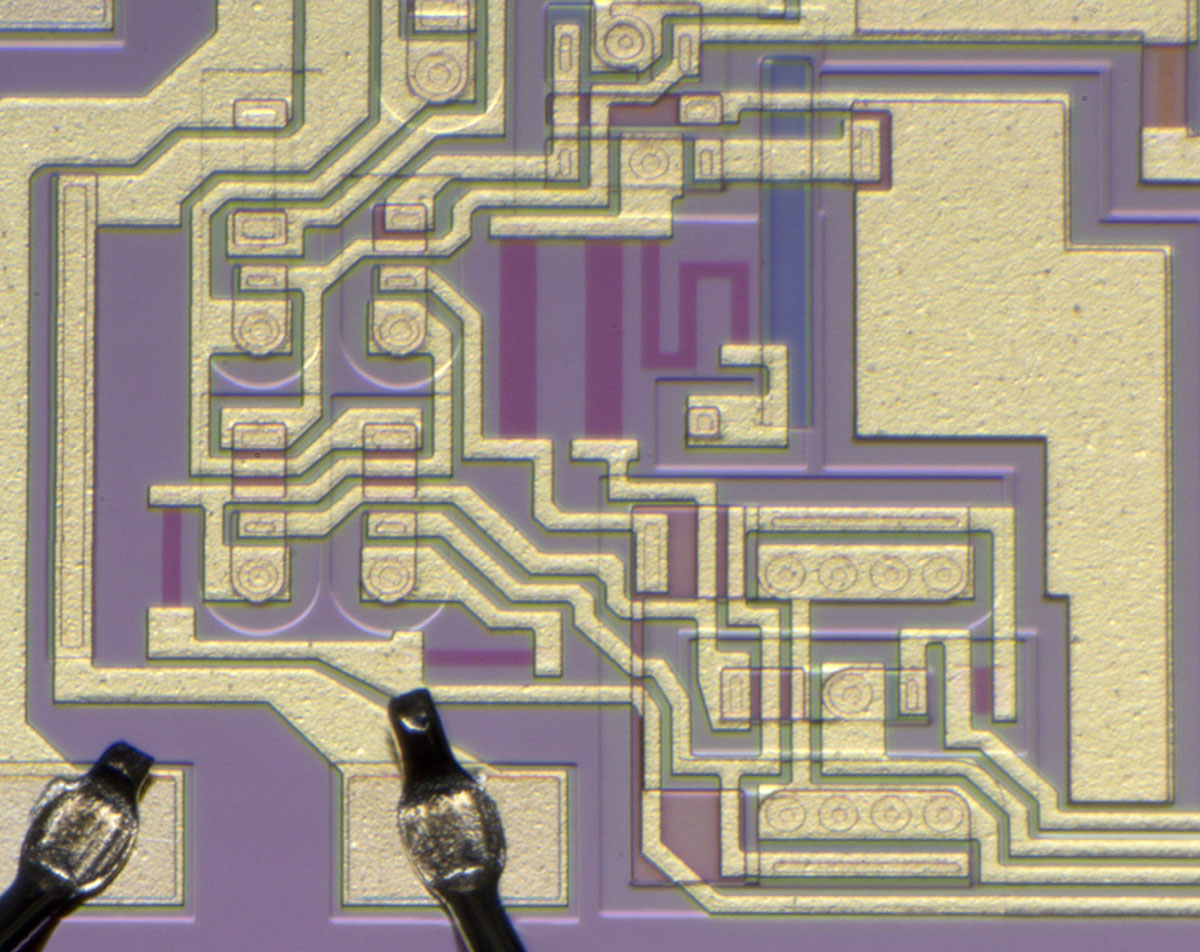

The core of the bandgap reference shows the typical structure. On the bottom right, a small transistor is surrounded by a large, two-part transistor. This ensures that both transistors behave as similarly as possible.

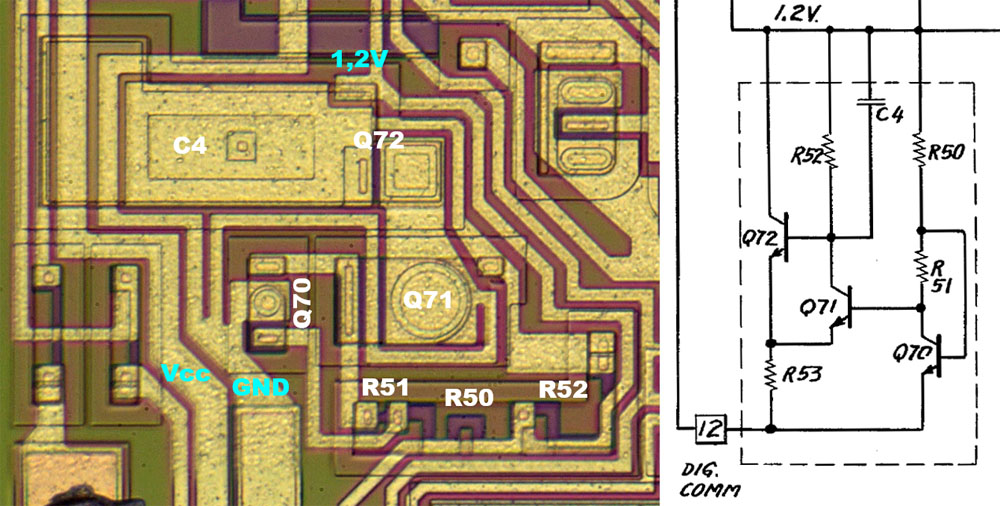

In the shunt regulator for the 1,2V bias, it is noticeable that resistor R53 is missing. R53 is also not visible in the metal layer of the first revision.

The transistor Q72 and the capacitor C4 are integrated into each other.

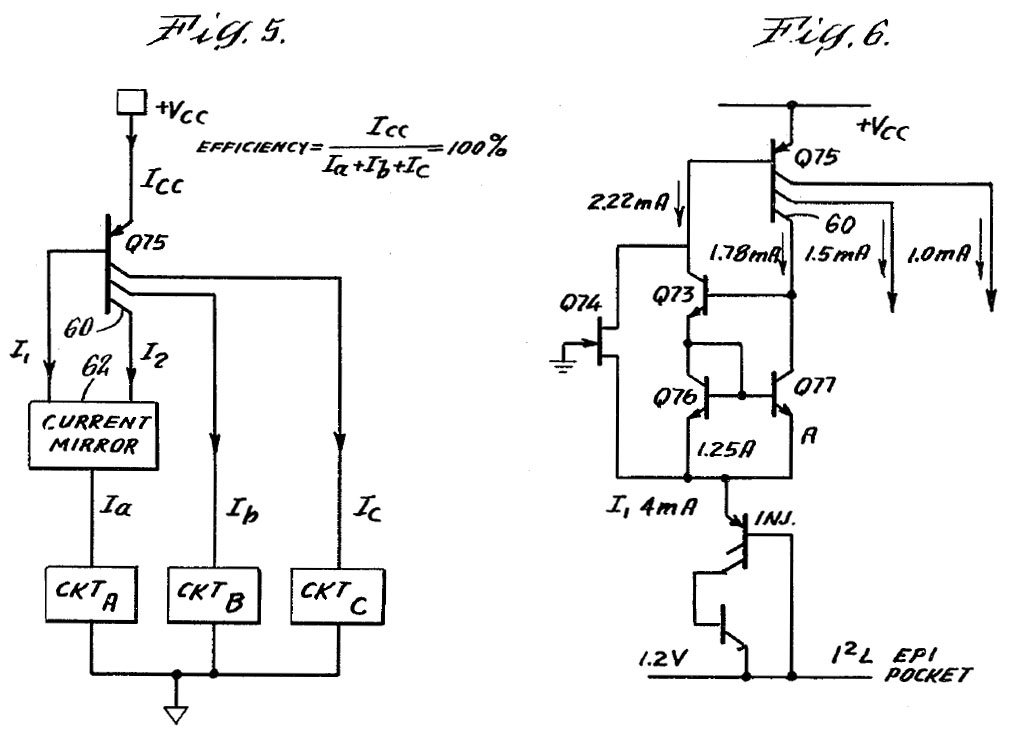

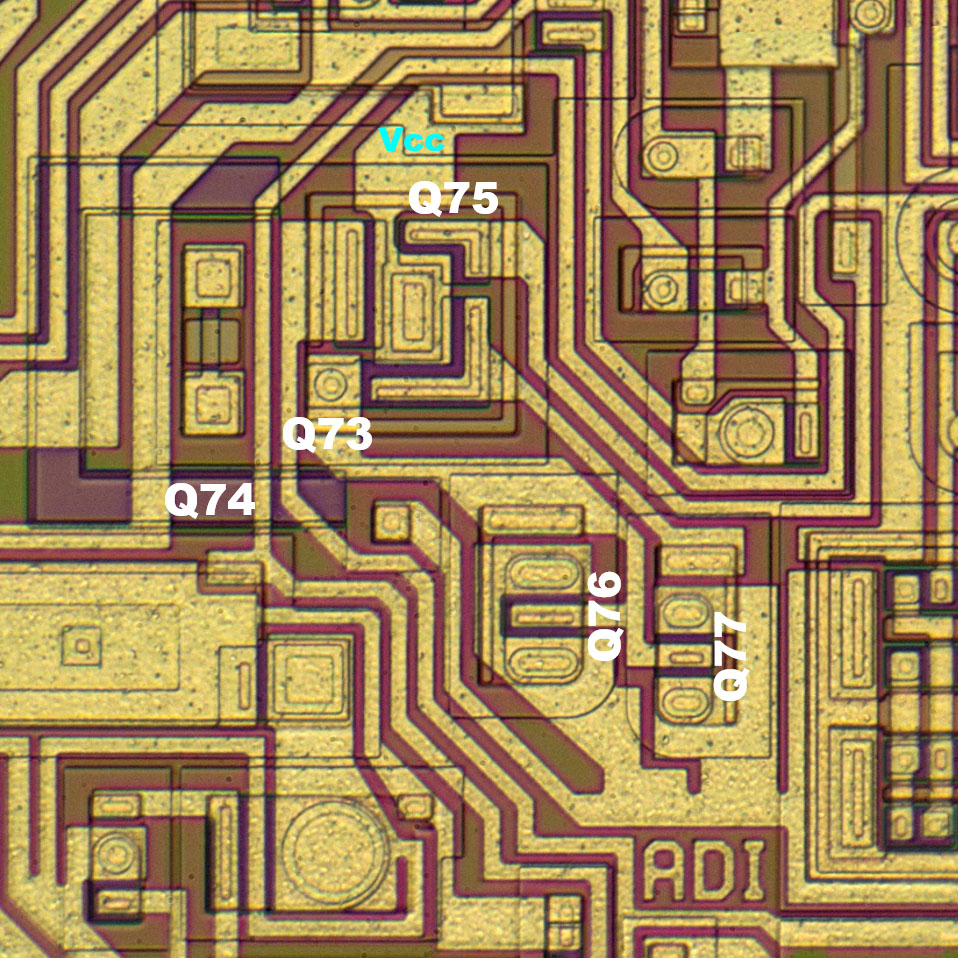

The patent US4323795 emphasizes the efficient generation of the necessary, relatively high working currents. The geometries of the current mirror Q75 and the current mirror Q73Q76/Q77 have been matched so that a constant current is established (Ia). This current can be used directly as a bias current and there is no need for the classic reference path, whose current flow is lost for the actual circuit.

The current source thus supplies the I2L circuit with 4mA, the control output of the bandgap reference with 1,5mA and the control circuit of the I2L buffer with 1mA.

The implementation of the current sources on the die features some interesting structures. Three large collector structures are integrated around the PNP transistor Q75. Due to the close electrical connection, the NPN transistor Q73 is located directly inside these structures. In the lower area, you can see the differently sized transistors Q76/Q77, which supply the I2L area following to the right.

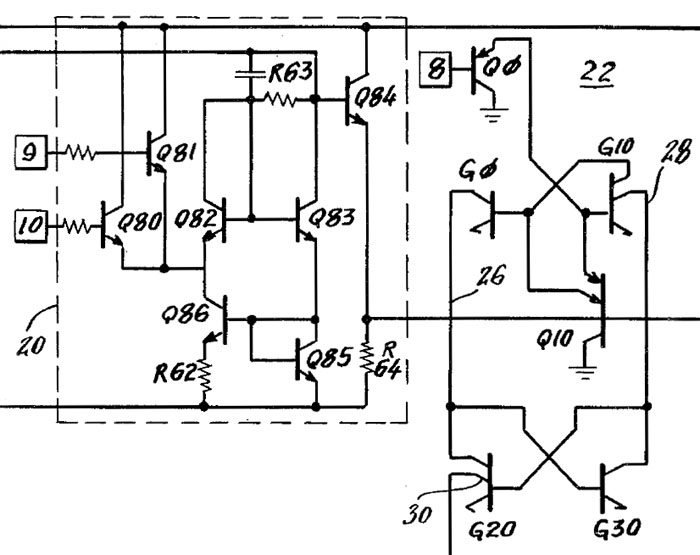

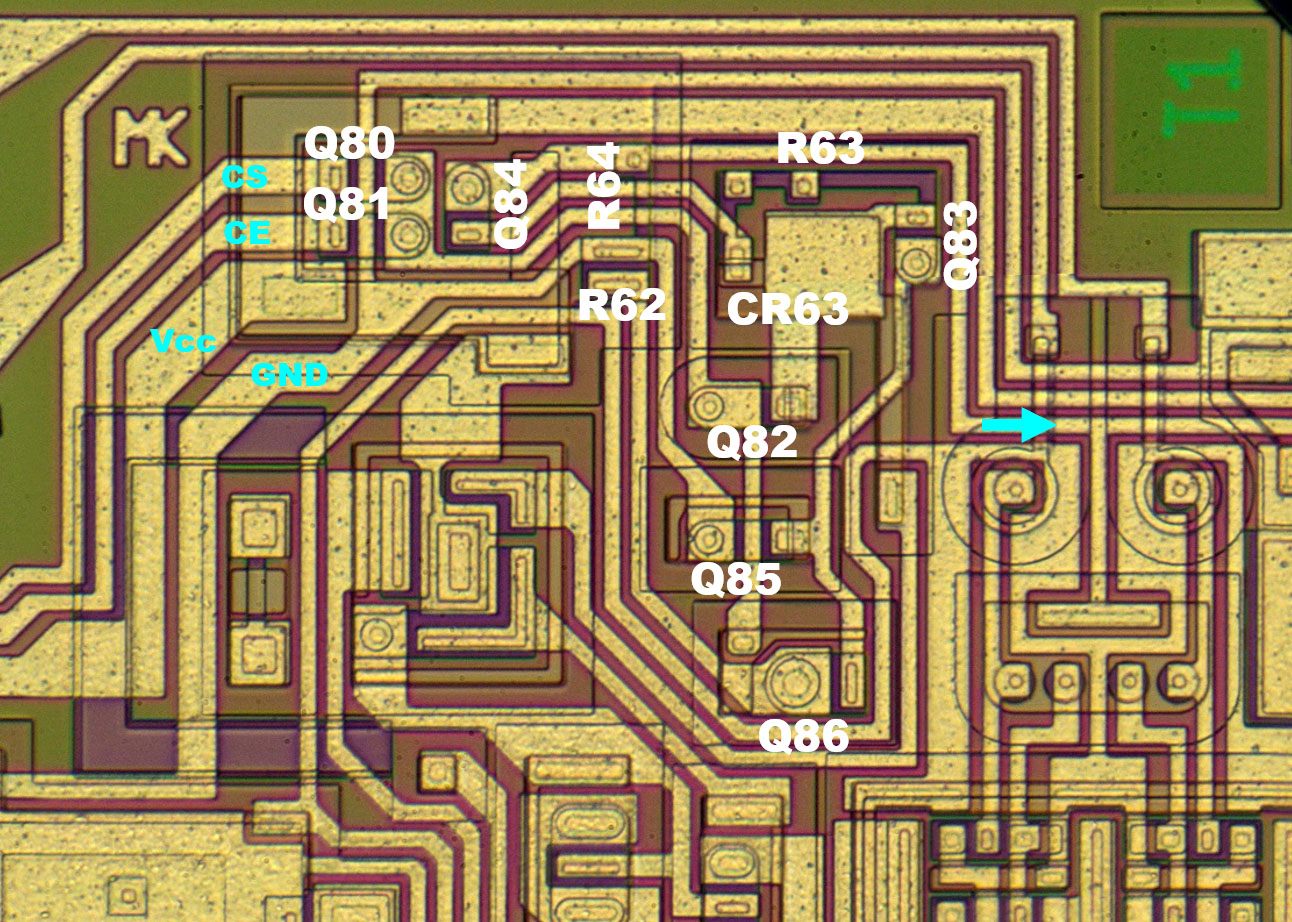

A small circuit links the control signals CS and CE and thus controls the transfer of the applied digital value into the lath.

The transistors with the half emitter arrows are constructed as Integrated Injection Logic (I2L), as described in more detail in the context of the CA3161 (

https://www.richis-lab.de/logic22.htm).

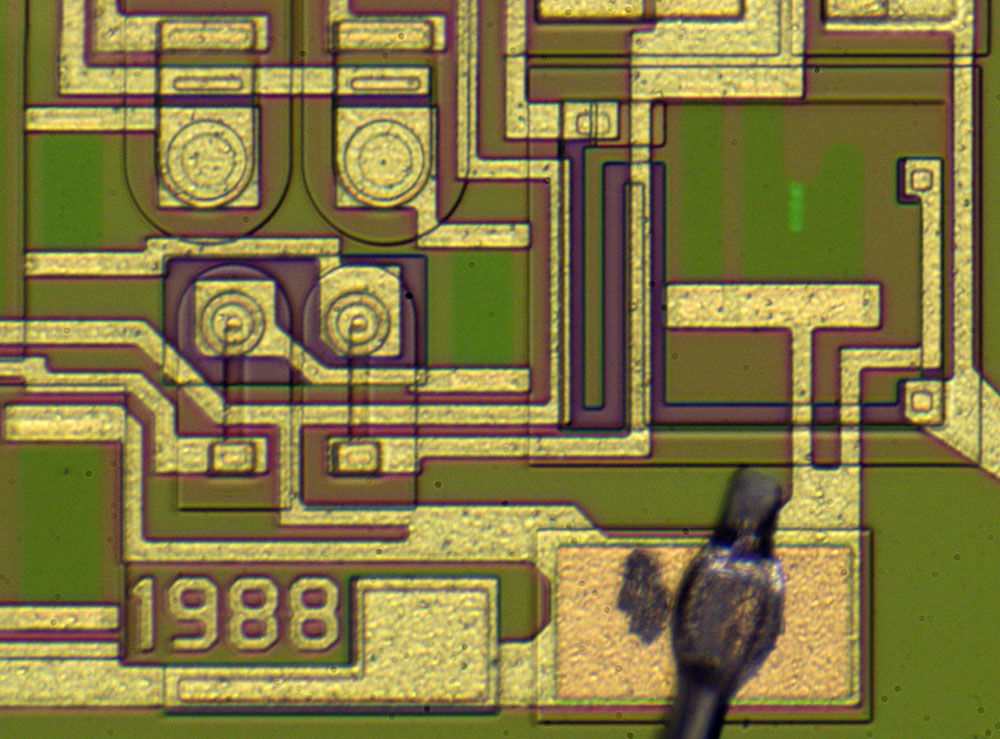

The control circuit of the buffer is integrated in the upper left corner. The resistor R63 has two additional contacts and can thus be adjusted by changing the metal layer. This changes the switching threshold of the inputs.

The use of I2L technology made it possible to integrate the latch in a very space-saving manner. The injection current is fed into the area from the current source on the left and contacts the individual I2L elements with quite low resistance.

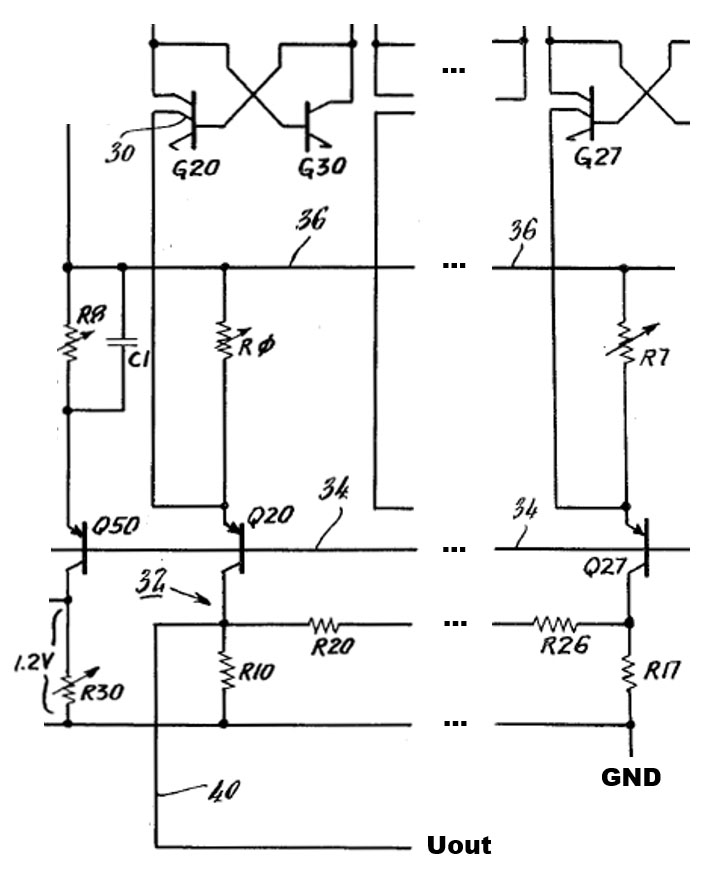

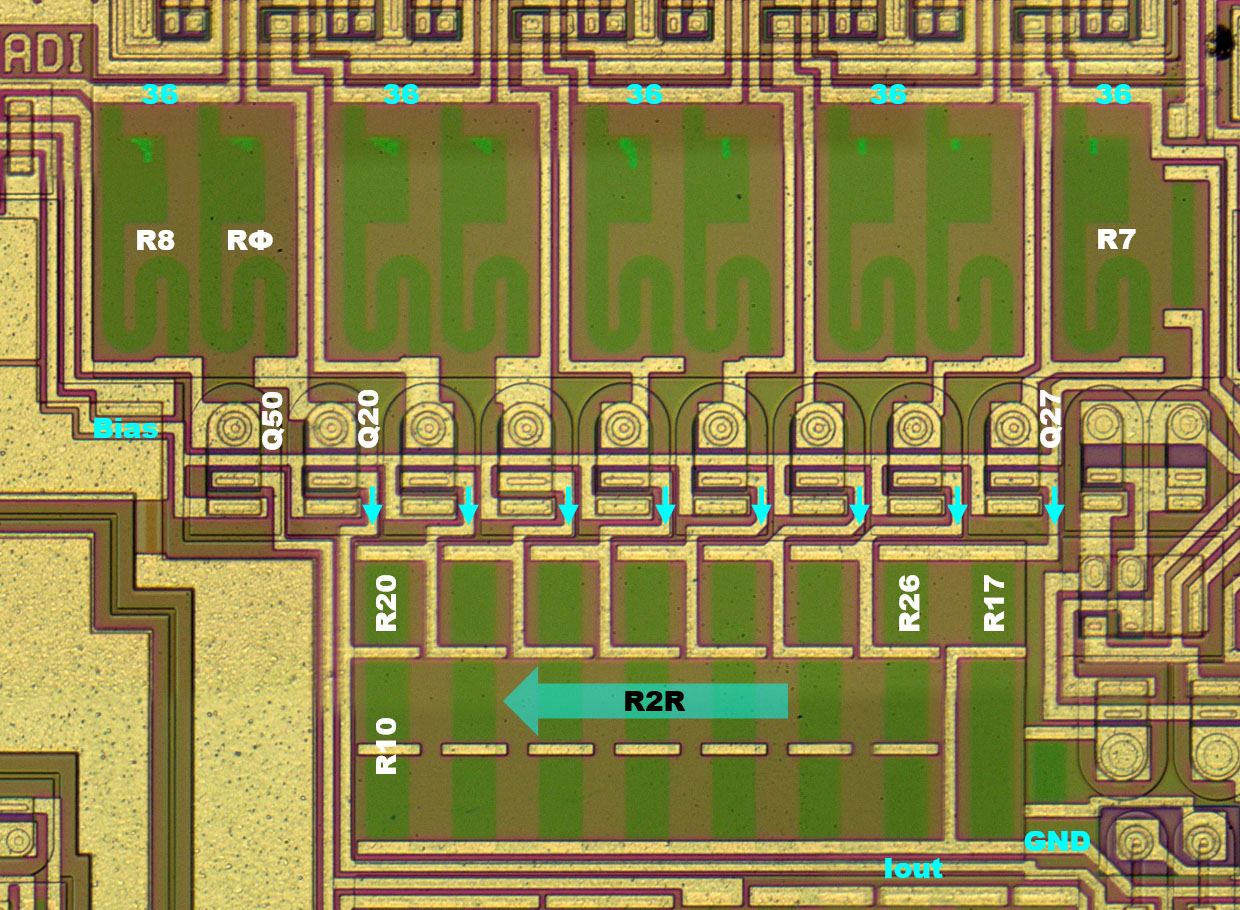

The actual DAC is shown in abbreviated form in the patent circuit. The emitter resistors of the current sources are adjustable to be able to represent a high accuracy. Below the current sources is the R2R divider, which ensures that the current sources further to the right only contribute a portion according to their weighting. The output voltage adjusts between 0V and 400mV.

The reference current source (Q50) is integrated directly next to the eight current sources of the DAC and has exactly the same shape. This measure ensures that all current sources behave as identically as possible.

The emitter resistors are clearly visible. Every resistor was tuned. However, the right elements show less alignment traces. The accuracy requirements are lower because of the smaller contribution of the current sources and probably less effort was put into the tuning.

At the top edge, the emitter potential "36" is distributed. In the middle, the PNP transistors generate the necessary currents whose contributions to the output voltage are scaled in the R2R network. To achieve a high symmetry with the resistors, there is a resistor strip under R17, although it is not needed in the circuit.

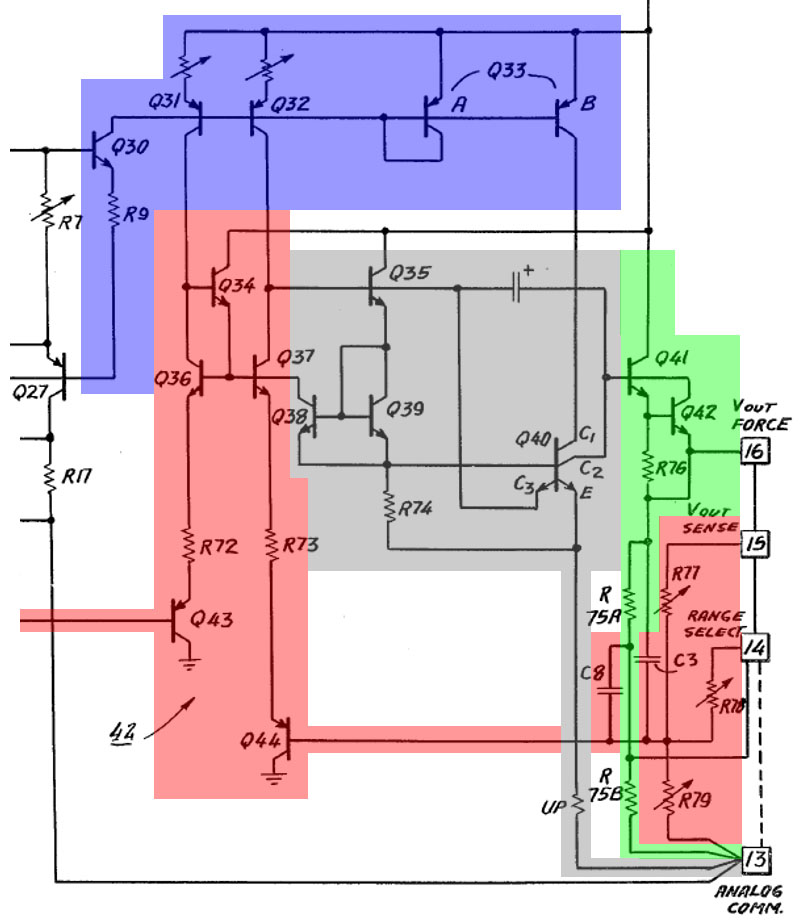

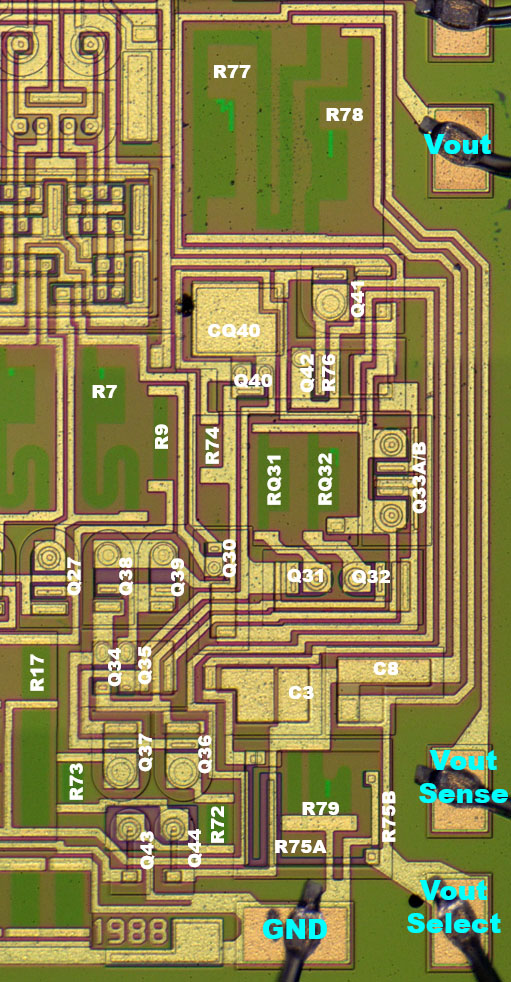

The output amplifier uses the potentials of the DAC current sources to generate its bias currents (blue). The input stage (red) has an unusual design. PNP transistors Q43/Q44 process the output signal of the DAC and the feedback that is fed back from the output. They are located in the emitter paths of current mirror Q34/Q36/Q37.

At the collector of transistor Q37 the signal is passed to the next amplifier stage (gray), which controls the output driver Q41 (green). With R76 Q42 represents an overcurrent protection. Depending on the external connection of the resistors R77/R78/R79, an output voltage range of 0-2,56V or 0V-10V can be set. If the external wiring is missing, the resistors R75A/R75B form a certain negative feedback.

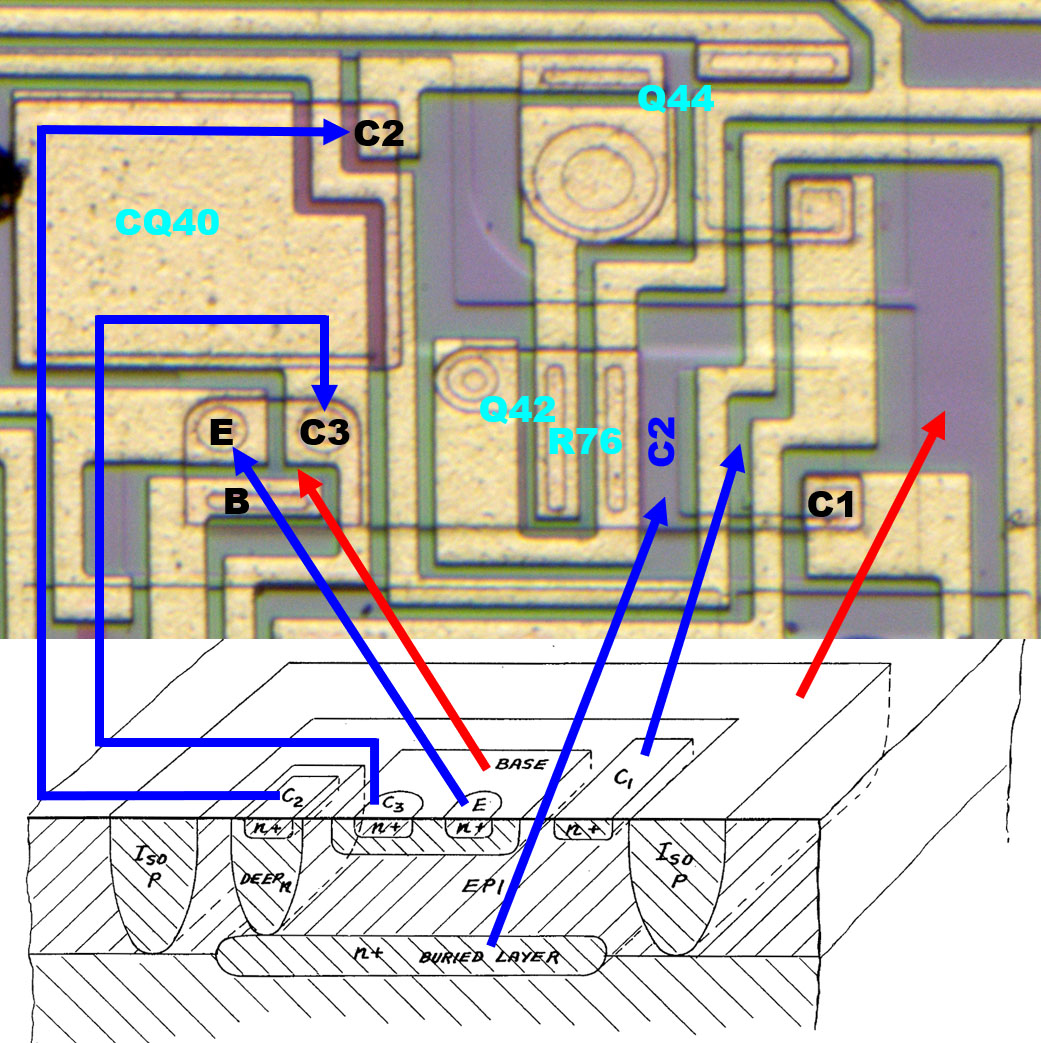

The gray circuit contains a very unusual element with the transistor Q40. The illustration shows a transistor with two emitter terminals and two collector terminals, with one emitter terminal designated C3. The patent US4323795 explains that this particular transistor was integrated to compensate for a fundamental problem that arises when one wants to operate DACs without a negative supply. When the output signal approaches ground potential, the driver stage tends to saturate, which severely degrades the dynamic range of the amplifier.

The additional emitter C3 improves the saturation behavior. In normal operation, no current flows across it. However, if Q40 goes into saturation, the potential at C3 drops below the base potential of Q35. In this state, the additional emitter behaves like a collector and sinks base current from Q35. This results in Q40 being driven less and leaving saturation. The additional collector C2 just provides a Kelvin connection to the collector C1, which reduces the voltage drop in the path of the output stage.

In the output amplifier, the adjusted resistors for the current sources and the voltage divider of the output voltage are clearly visible.

Without the description in the patent it would be difficult to recognize the function of the transistor Q40.

The patent shows a sectional view of this special transistor. C1 and C2 represent a normal collector, with C2 being more low-impedance connected to the active area via a buried, highly doped layer. C3 is a heavily n-doped region within the base area and thus represents an emitter rather than a collector.

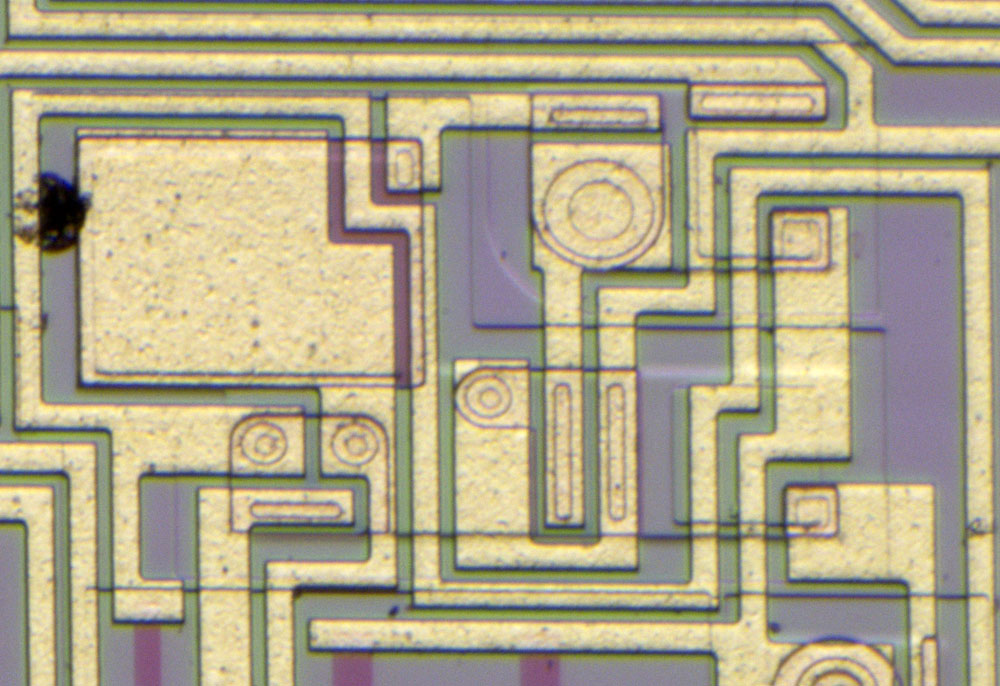

In the real structure, the two emitters have the same structure. On the far right, the collector C1 is contacted. The nearly square area then is the surface n+ doping. In the middle of the structure Q42, the current limiting transistor of the output stage, is integrated. Since its collector potential is the C2 potential, it directly uses the collector area of transistor Q40. Shunt R76 has been integrated here too.

The buried collector extends over the whole area of the two transistors and further to the upper left, where it widens and represents the lower electrode of the capacitor CQ40. Finally, the connection from the collector C2 to the output transistor Q44 is located there.

The two PNP input transistors of the output amplifier show an interesting structure. Since the n-doped base is formed via the collector structures of the NPN transistors, a buried collector feed line could be used here in order to be able to represent the undercrossing of a metal line with low impedance. This collector (now base) feed line shows up here as a thin line within the weak n-doped elongated rectangle.

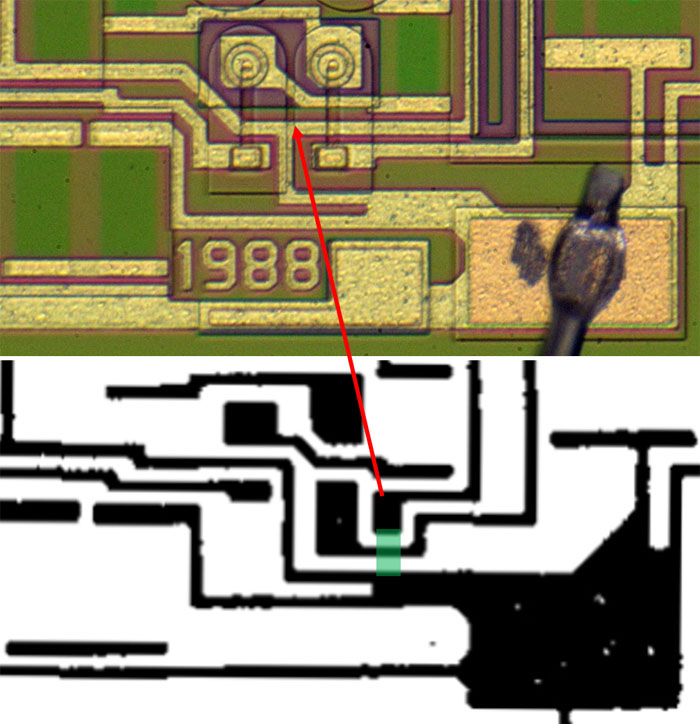

In the schematic in the patent the transistor Q40 is connected to the emitter resistor Rup. On the die this resistor doesn´t exist. The metal layer of the older revision shows that in this version the resistor was probably still present (green).

https://www.richis-lab.de/DAC24.htm