I've also tried scoring with a blade and breaking, which didn't work much better.

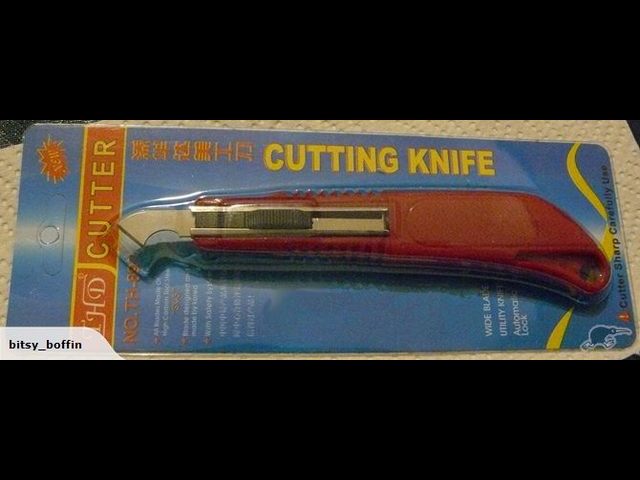

I think that scoring and breaking is your best option for a clean cut, but you REALLY have to score fibre based boards DEEP, and you must do it on both sides. I bought some "hook knives" from China, this is the knife that the taobao vendors etc use to cut up blanks, and it does work pretty well (when I can find it, when I can't I just resort to a normal craft knife, but takes more scoring passes).

Start the score with the tip, then switch to the hook and rip it down. Clamp the pcb with a ruler along the score line. Also works good for acrylic sheets.

(NB: I haven't tried cutting board with resist already on it, so no idea how cleanly it cuts in that situation)

I see there's a couple on eBay

http://www.ebay.com.au/sch/i.html?_from=R40&_sacat=0&_nkw=pcb+hook+knife&rt=nc&LH_PrefLoc=2Or... get yourself some dry film and laminate the board after you've cut it :-)

/Aside: resin type boards (phenolic) are so much easier for the hobbiest, score score snap done, and much easier on drill bits, one of these days I'm going to see if I can track down double sided phenolic.