This is related to some other conversations about ovens and thermocouples, etc. I am trying something new and thought it timely to share.

I wanted to use a copper sheet in my electric imp-controlled reflow oven but I assumed that the shiny surface would not receive the radiated energy very well.

To hep the heating I tarnished a copper sheet using a solution of Liver of Sulfur and distilled water at 60C. I did a really quick and easy test and it seems to work well so far.

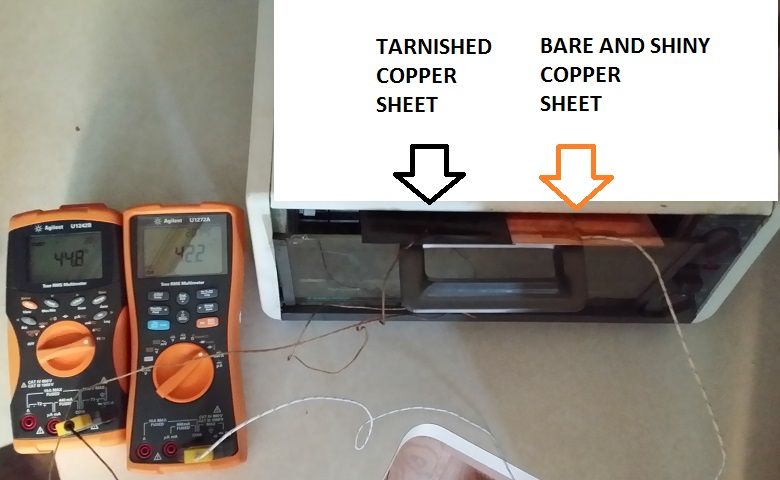

Thermocouples were taped to each sheet and I put them into my toaster oven (not my reflow oven but actually the one I use for toast every morning : )

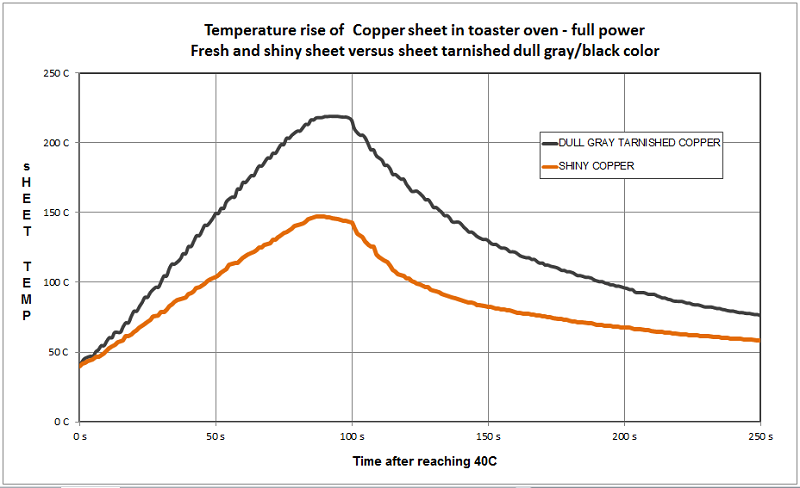

Somewhat interesting is that initially they appear to rise at the same temperature but starting around 40C the tarnished one really starts to take off. The shiny copper one had an initial rise of 1.2C per second. The tarnished one has an initial rise of 2.2C/sec. To double-check I dipped a bit of paper towel in water and checked the sizzle. The difference was quite remarkable so even if I have a bit of error from the thermocouple mounting I am sure the results are real enough.

This is a picture of the experiment setup. The Agilent meters have Bluetooth modules on the back so I logged to the Android app.

The next step is to do real reflow jobs with the tarnished plate. On the down-side the radiation heat will not go directly to the bottom of the board as it used to. It will now go to this plate and there will be a mixture of poor conduction and radiation to reach the bottom of the PCB. Meanwhile the top of the board and all the components will be exposed to the top heating elements.

Overall the big goal here is to obtain 1. good soldering results, possible for multiple boards. 2. good temperature feedback that can be correlated to board temperature.