For V2.05 power supply, I would add a ground wire that connects PE ground from the IEC connector to the 24VDC(-), and it should connect to the metal case (I use the encoder mounting tab to solder a wire there) as well.

To add on to this, I have some information I gathered today by testing my recently acquired KSGER T12 soldering station, V2.05 power supply board (black color).

A major challenge was that there's really nothing you can assume to be correct on these Chinese boards. My mistake was assuming that if there's a black wire and a red wire going to the DC board, black is negative and red is positive.

Turned out that the crimp connector was more of an afterthought and the wiring is completely inconsistent. While usually you'd wire connector cables so that it doesn't matter which end you plug in where, with this board revision (or at least my unit), they wired the connectors in mirrored fashion, so that if you plug them in the other way (power board end where DC board end should go), the wire colors are wrong (red for negative and black for positive).

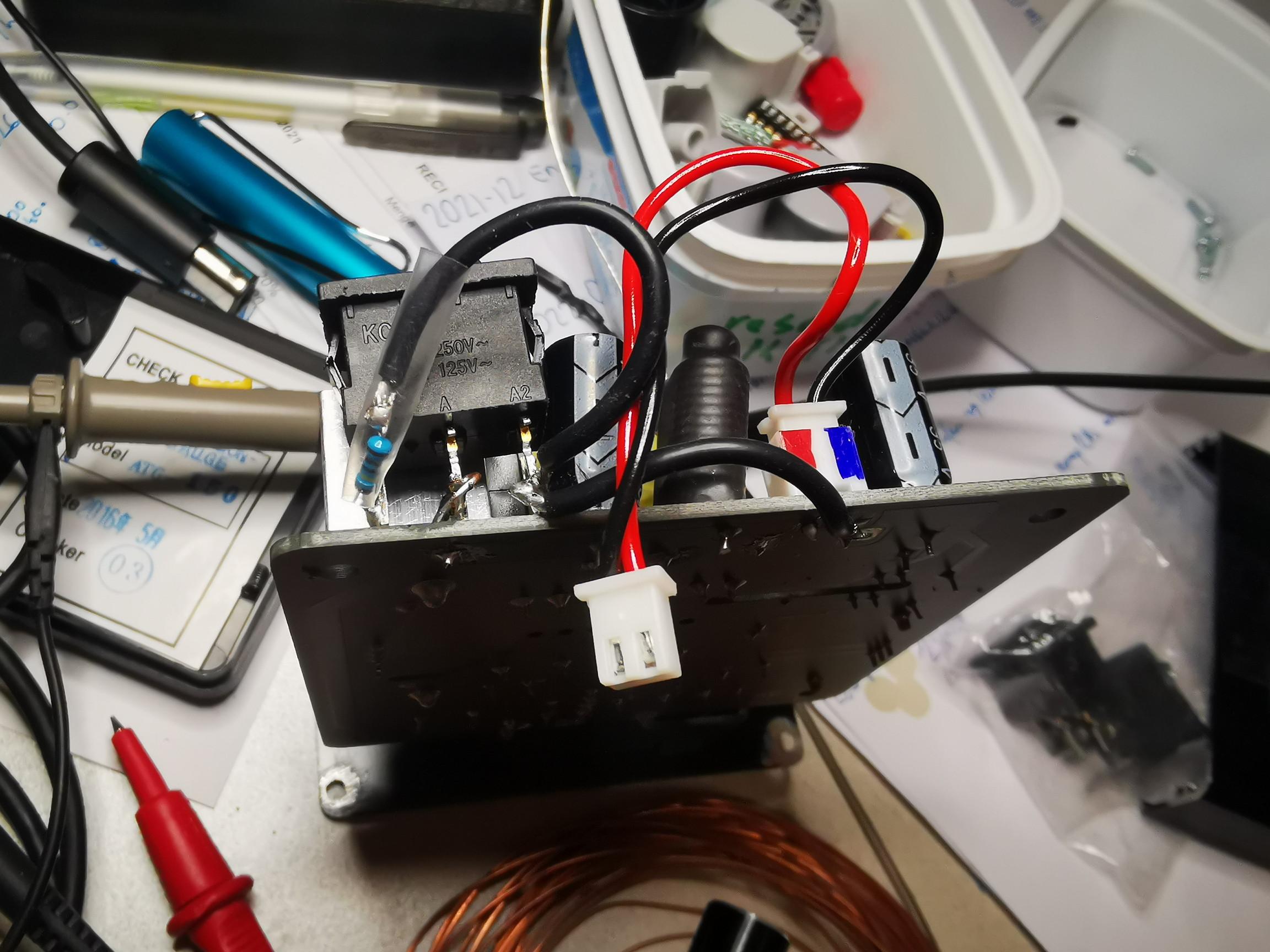

I painted marks of red and blue color for which wire is supposed to be in the respective spot.

Earlier today, when I assumed the spot where the black wire was originally (red spot marked in the picture above), I soldered Protective Earth to that solder point and thus to DC+. I was puzzled as to why my voltmeter showed -24V on the hot soldering iron tip, but with the confusing wiring it now makes sense.

Of course, soldering protective ground to DC+ is not a good idea at all, so I figured I'd post about this to hopefully prevent other people from encountering the same issue.

Since the question of direct ground vs. 1M resistor was talked about here, I decided to install a toggle switch (shown on the left in the photo above) to switch between infinite, zero and 1M resistance and check the noise levels at the tip with my oscilloscope for each.

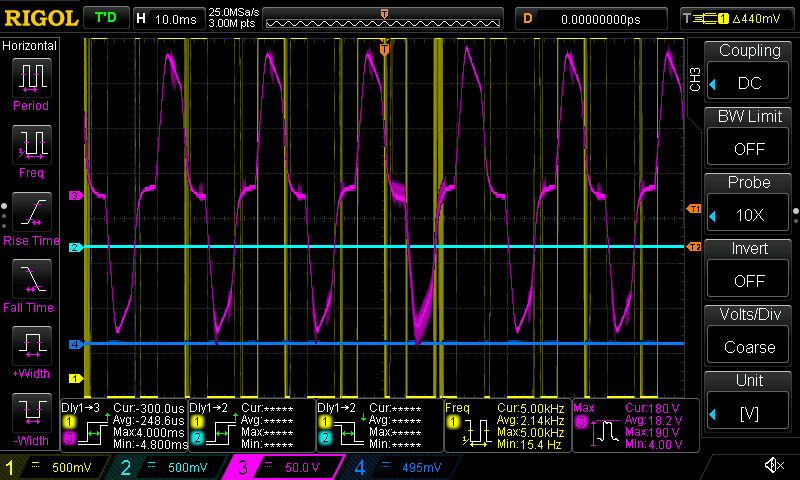

With the tip floating, as it does by default, there is some severe noise when measured with Protective Earth as a reference:

Both pink and yellow here are connected to the hot soldering iron tip, yellow is set to much higher sensitivity. Noise is so bad by default that the high sensitivity yellow line exceeds the display area by a lot. Even on the pink line, we still have extreme noise with up to 180V.

Toggling on the 1M resistor helped decrease noise levels by a bit:

However, we still have a maximum of 122V, personally I don't feel very safe soldering on any components this way.

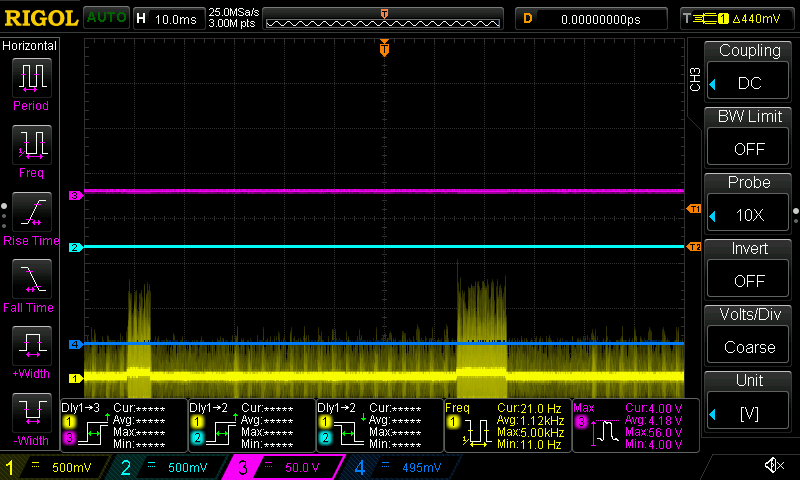

With direct ground connection, things get much, much better:

With the default vertical scaling, noise level was now too low to give accurate values for the 50V max display. Since I didn't want to mess around with my oscilloscope measure settings from what I usually use them for too much, I adjusted the pink signal line to 1V to get precise noise level values:

Now, noise level is at around 1.2-1.5V, a range that I feel okay with.

For reference, I measured my Ersa Analog 60 station as well, where the tip is connected to ground by default:

I'm not an expert with electronics at all, so I'm not sure how much the measured ~170V AC at the tip matters, since it's measured respective to Protective Earth that it's floating against. I'd appreciate an expert's estimation for sure. Perhaps the voltage looks worse on the scope than it really is effectively.

What I did notice is that, when measuring the voltage with a multimeter set to DC 200V, again with the COM wire going to internal Protective Earth, it only fluctuated between about -2 and +4V. Not sure whether that just means that the voltage was fluctuating too quickly for the multimeter to pick up accurately. In that case, probably I should have set it to AC instead, something I forgot to do.

After having spent 8 hours today researching about and working on this multimeter, I don't really want to put any more time into it right now though.

Related to that, my next soldering station purchase, whenever that will be, will definitely be a JBC or similar. When I take into account the time spent on fixing all the minor issues of these Chinese KSGER / Quicko stations and their handles, 300€ for a JBC doesn't seem like much any longer.