Hello to everyone.

For a current project, i need to build a circuit that can detect, if the Voltage between to contact points exceeds about 50VDC.

If that is the case, two functions must be achieved:

1. An optocoupler has to give signal to another low-voltage side. For this a have an additional 12V Power-supply.

2. A visible LED has to turn on. The problem here is, that i can not use any other supply-voltage, then the one that i am measuring.

The Measuring-Voltage can range from 0 to 600VDC.

First i want to focus on function number 2.

I have build a circuit that fulfilled these requirements based on an LR8 Voltage-Regulator in the past, but it uses a bunch of components.

Since my functionallity is basically the same as a contact-Voltage-tester, i thought, there must be a simple way to do this.

Unfortunattely, i do not have a voltage-tester to spare, to take it apart and reengineer the circuit.

I tried figuring out something on my own.

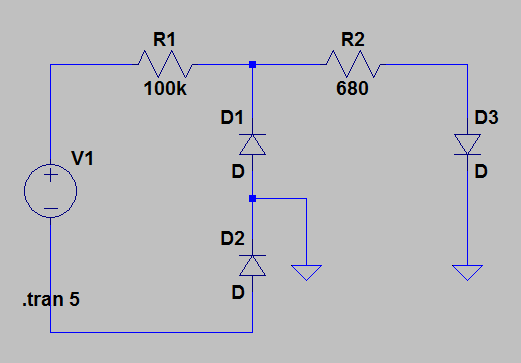

D1 = Zener, ~40V

D2 = Zener, ~6V

D3 = LED

R1 = Current Limiting Resistor

R2 = Current Limit for LED

But with this approach, because of the high input voltage range, either the used energy gets quite high, or i do not have enough energy to drive my led reliably.

Am i missing something?

Or does anybody have a hint on a better solution?

Or maybe someone has a scematic of a contact-voltage-tester?

I would be thankfull for all input!

Greetings,

Philipp