I guess my first question is which version of FreeCAD are you referring to?

In the old version (discussed earlier), it is not possible to create multiple parts.

As far as order is concerned, in many times you don't have a lot of choice.

Certain operations depend of previous ones. For example, you can't cut a hole in a part

you haven't created. If you wanted to add a plate to the knob as you suggest, you would

just create a new sketch to the last operation in order to create a pad or perform a

revolution operation. In the newer versions of FreeCAD, you can create multiple bodies

to build up your model.

The order you create the model depends a lot on what you're modelling. Most likely, you

will build the model from the inside out. Mainly you create a sketch, use that sketch

to perform a further operation (pad, revolve, cut), and then a boolean operation in some cases.

After you're comfortable, you can move to the 'draft' workbench to add text. More advanced

operations to learn are the loft and pipes to create a curved surface or to draw a sketch along

a path. In the beginning, you try to do things a certain way and find out you can't get from

point A to point B and will need to do it differently. Especially in the older versions.

I do most of my modelling in the 'part design' workbench building sketch upon sketch.

Think of a sketch as the shape of the tool you will use to draw with.

I can suggest a few YouTube channels:

-

https://www.youtube.com/playlist?list=PL7eiW2bt21YU6QEbly78kUgQCNEiDUwSH -

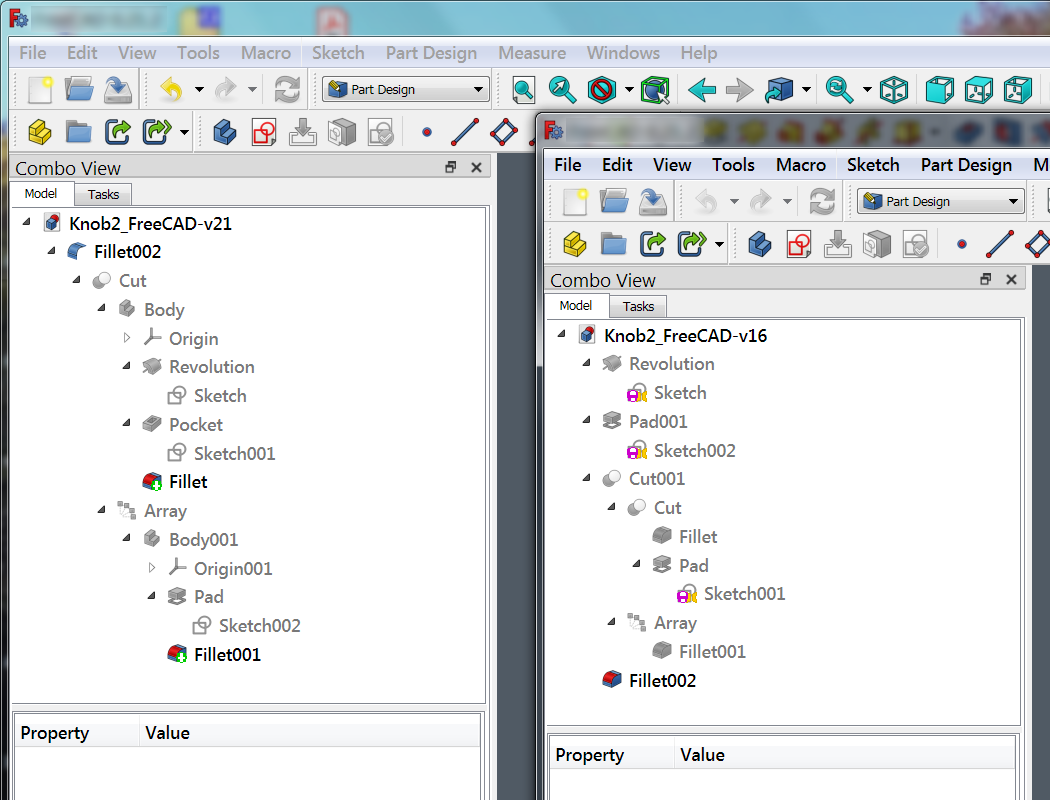

https://www.youtube.com/playlist?list=PLWuyJLVUNtc0UszswD0oD5q4VeWTrK7JCPerhaps a photo of the two versions of FreeCAD: